- 19

- Dec

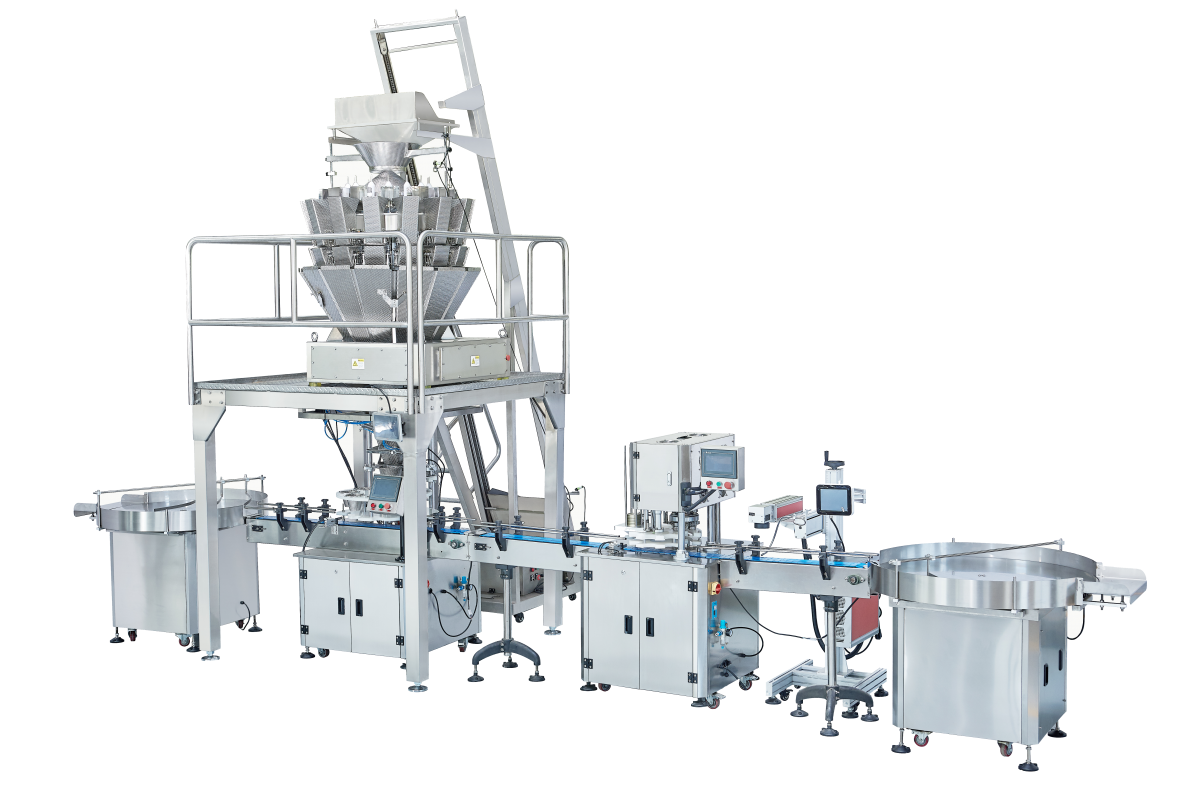

Automatic Granules Product Weighing Filling Seaming Machine Line

Machine Line with can accumulation table, mutil head weighing filling system (auto lifting, platform, weighing filling ,rotatry can feeding machine) , automatic can seaming machine, can collector

This line is suitable for all kinds of granules and solid materials, flexible machine materials can be selected according to product materials, for example oats,bean,coffee bean,nuts,hazelnut,pistachios,cranberry,dry fruit etc.

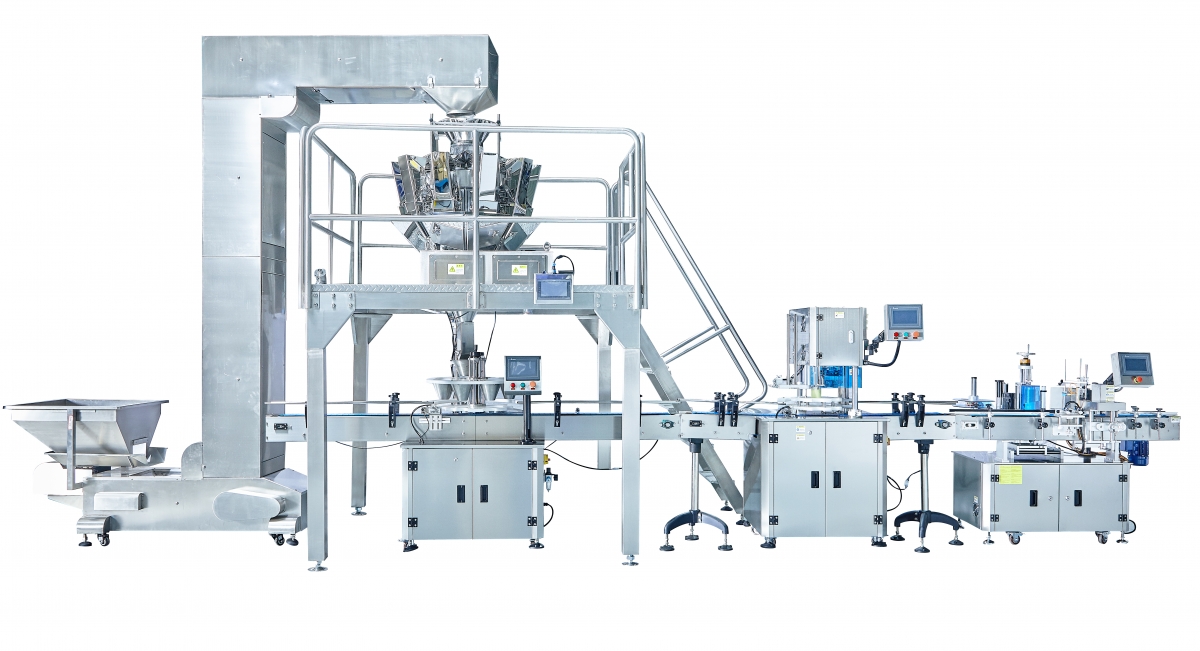

Machine line with Weighing filling combination (hoist,platform,10 heads weighing filling ,can filling machine) , automatic can sealing machine,automatic can body labeling machine

Machine line with can sorting machine,can inside blowing cleaning and UV sterallization,10 heads weighing filling system,automatic capping machine ,laser printer .

This machine line is suitable for all types of granules product with lock cap machine

Machine Line Introoduction

Can Accumulation table and Can collector

1. It can accommodate a large number of cans at a time, automatically sorting into the conveyor belt of the packaging line, saving labor costs, improving production line automation, and thus improving production efficiency.

2. Simple structure, easy to operate and use

3. Can be used at the front and the end of the packaging line according to customer requirements

Empty Cans Ultraviolet Sterilization Cleaning Machine

1. The empty can ultraviolet sterilizing cleaning machine is mainly composed of cleaning part, germicidal lamp part, conveying part and control part, etc.

2. This machine can clean and sterilize empty cans, and its circular operation structure is in the leading position in technology among similar cleaning and sterilization machines.

3. The control of the whole machine adopts the centralized control of the panel, which is more convenient to operate;

4. The cleaning part is equipped with a filter device, so as to realize zero dust pollution to the environment during cleaning

Weighing Filling Machine System (Hoist+plastform+multi head weighing filling +can feeding machine)

1. It adopts deceleration lifting , automatic feeding control system when material is missing, and the bucket type lifting mechanism is completely closed, non-polluting, no leakage, feeding, weighing, filling, and full automation control.

2. Equipped with domestic well-known ultra-miniature combination, the filling speed is fast and the precision is high. Multi-language touch screen human-computer interaction system, visual operation, can also record the total number of cans, pass rate and single can error of each batch.

3. Suitable for all kinds of granules and solid materials, flexible machine materials can be selected according to product materials

Automatic Can Sealing Machine

1.Whole machine servo control makes the equipment run safer, more stable and smarter.

2. The sealing speed can reach up to 50 cans per minute, high production efficiency.

3.The whole machine has a transparent blue acrylic cover, multiple protection, more beautiful and safe.

4.Applicable to tin cans, aluminum cans, plastic cans and paper cans, it is the ideal packaging equipment for food, beverage, Chinese medicine drinks, chemical industry etc.

Optical fiber laser marking machine

1. Applicable to the outer packaging of metal, such as milk powder cans, beverage tin cans, etc.

2. Cooling by air cooling, good heat dissipation

3.The fiber can be coiled, the output beam quality is good, no adjustment, no maintenance, high reliability