- 26

- Nov

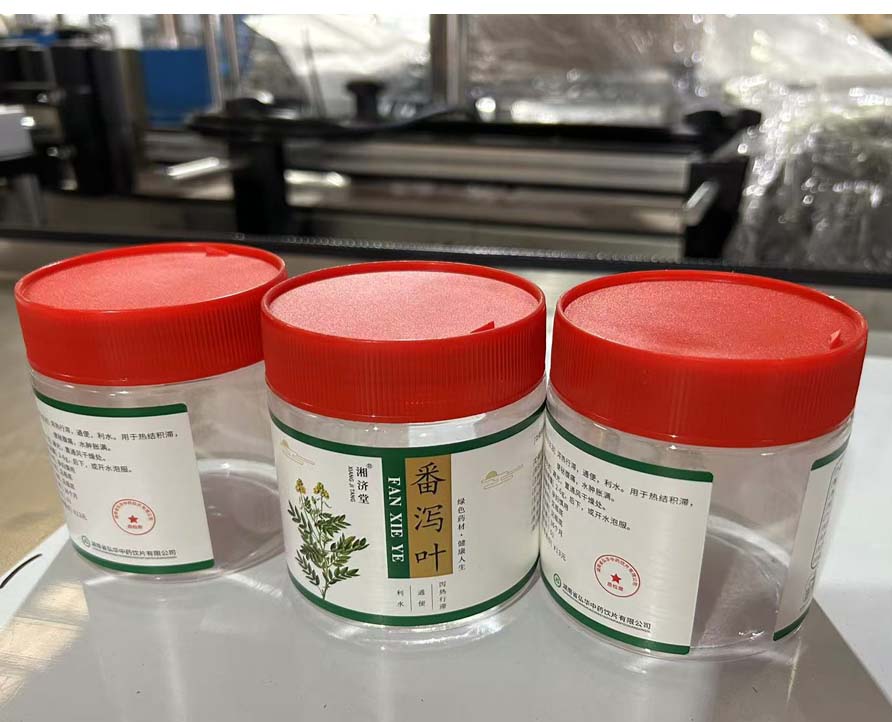

Automatic Capping Machine with Single Head, Screwing Capping machine for bottle , bottle capper machine

Automatic Capping machines are widely used in food, pharmaceutical, daily chemical, pesticide and cosmetic industries.Capping machines can adapt to the needs of different bottle shapes

Automatic capping machine supplying caps, clamping bottles, conveying and screwing caps are all completed automatically.

The machine has good stability and is easy to adjust,lower cover air gripper is more stable and reliable.

Automatic capping machine can be adjusted according to the height of the bottle and the size of the bottle cap, and the tightness can be adjusted according to customer requirements.

Automatic Capping Machine parameter

- Capping method: air gripper capping.

- Capping method: lifting belt capping, guide rail and capping assembly for different caps

- Capping speed: 900~1500 bottles/hour

- Capping method: servo torque-limited gripping capping

- Capping speed: 900~1500 bottles/hour

- Total power: 1KW

- Casing material: 304 stainless steel plate

- Capping motor: Delta servo motor 9. Dimensions: length 2800width 1400height 2100mm

- Power supply: AC220V 50/60Hz

- Air consumption (compressed air): 0.5-0.6MPA

- Current: 7A

- Applicable range: tank diameter φ30-φ125mm, tank height 30-220mm

Automatic capping machine improve production efficiency, reduce labor, be stable and reliable, reduce labor costs and reduce production errors

Automatic capping machine has a high-precision capping control system and a tightness control system, which can ensure the stability of the cap tightening, greatly reduce the incidence of quality problems such as cap leakage and cap loosening, and improve the quality and safety of the product.