- 02

- Jan

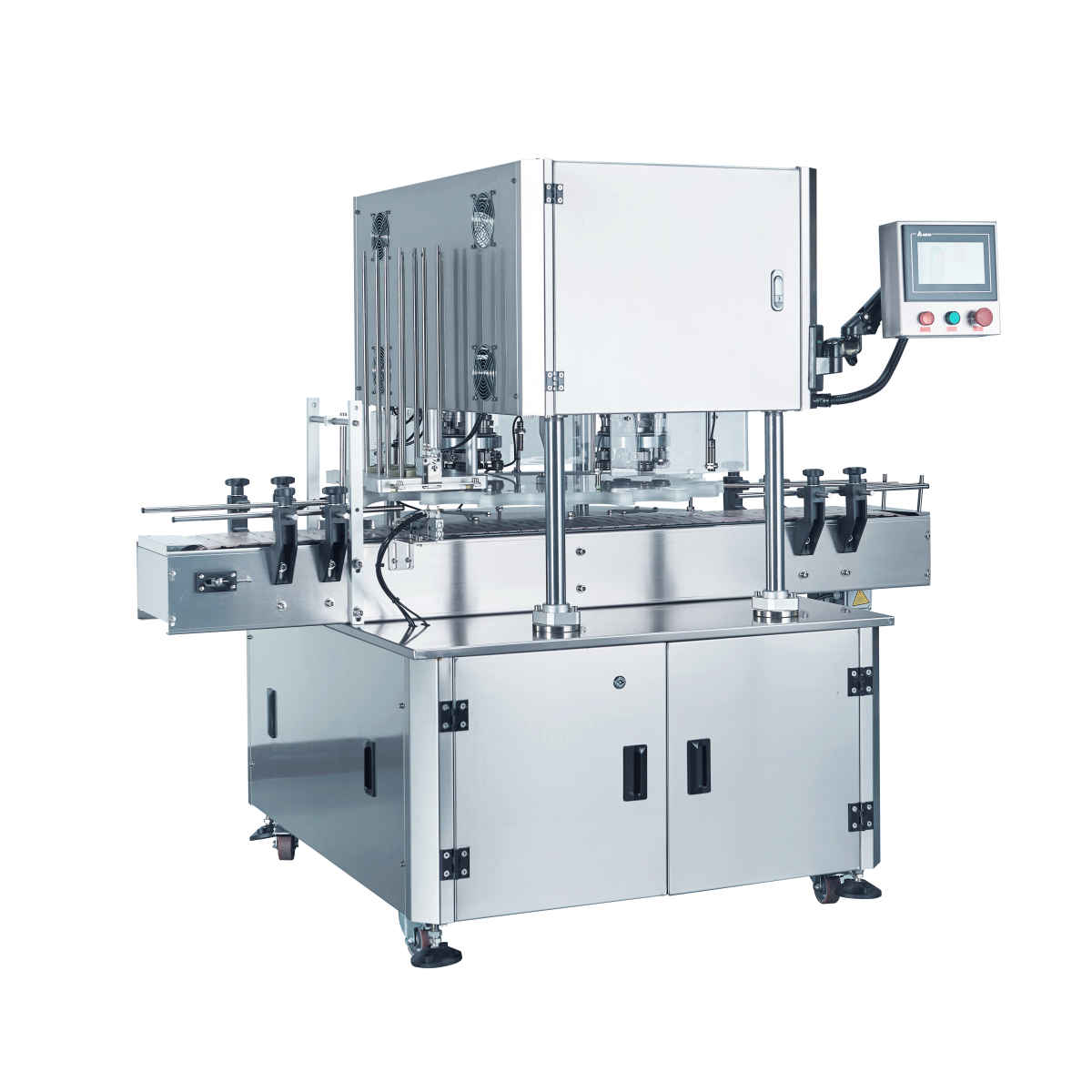

High Quality Dual Head Beverage Can Seamer

Benefits of Using a High Quality Dual Head Beverage Can Seamer

A high-quality dual head beverage can seamer is an essential piece of equipment for any beverage production facility. This machine is designed to seal aluminum cans with precision and efficiency, ensuring that the contents remain fresh and carbonated for an extended period of time. There are several benefits to using a high-quality dual head beverage can seamer, including increased productivity, improved product quality, and reduced downtime.

One of the primary benefits of using a high-quality dual head beverage can seamer is increased productivity. This machine is capable of sealing multiple cans simultaneously, allowing for faster processing times and higher output levels. With a dual head seamer, operators can seal twice as many cans in the same amount of time compared to a single head seamer. This increased efficiency can help beverage manufacturers meet production demands and fulfill orders in a timely manner.

In addition to increased productivity, a high-quality dual head beverage can seamer also helps improve product quality. The precision and consistency of the sealing process ensure that each can is properly sealed, preventing leaks and contamination. This is especially important for carbonated beverages, as a tight seal is necessary to maintain the carbonation levels and prevent spoilage. By using a dual head seamer, beverage manufacturers can ensure that their products meet the highest quality standards and provide a satisfying drinking experience for consumers.

Another benefit of using a high-quality dual head beverage can seamer is reduced downtime. These machines are built to withstand continuous use and are equipped with features that minimize the risk of malfunctions and breakdowns. This reliability helps prevent unexpected downtime and allows production to run smoothly without interruptions. In the event that maintenance or repairs are needed, dual head seamers are designed for easy access and quick servicing, further reducing downtime and maximizing uptime.

Furthermore, a high-quality dual head beverage can seamer offers versatility and flexibility in production. These machines are capable of sealing a wide range of can sizes and styles, allowing beverage manufacturers to accommodate different packaging requirements and customer preferences. Whether sealing standard 12-ounce cans or tallboy cans, a dual head seamer can handle the job with precision and efficiency. This flexibility enables manufacturers to adapt to changing market demands and expand their product offerings without investing in additional equipment.

Overall, the benefits of using a high-quality dual head beverage can seamer are clear. From increased productivity and improved product quality to reduced downtime and enhanced versatility, this machine offers beverage manufacturers a competitive edge in the industry. By investing in a dual head seamer, companies can streamline their production process, deliver high-quality products to consumers, and ultimately achieve greater success in the market.

How to Choose the Right High Quality Dual Head Beverage Can Seamer for Your Business

When it comes to packaging beverages in cans, having a high-quality dual head beverage can seamer is essential for ensuring a tight seal and preserving the freshness of the product. With so many options available on the market, choosing the right seamer for your business can be a daunting task. In this article, we will discuss the key factors to consider when selecting a high-quality dual head beverage can seamer that meets your business needs.

First and foremost, it is important to consider the speed and efficiency of the seamer. A dual head seamer is designed to seal two cans simultaneously, which can significantly increase the production output. Look for a seamer that offers a high speed of operation without compromising on the quality of the seal. This will help you meet the demands of a fast-paced production environment and ensure that your products are sealed efficiently.

In addition to speed, it is crucial to consider the durability and reliability of the seamer. A high-quality dual head beverage can seamer should be built to last and withstand the rigors of continuous use. Look for a seamer that is made from high-quality materials such as stainless steel, which is known for its durability and resistance to corrosion. Additionally, choose a seamer from a reputable manufacturer with a track record of producing reliable and long-lasting equipment.

Another important factor to consider when choosing a dual head beverage can seamer is the ease of operation and maintenance. Look for a seamer that is user-friendly and comes with clear instructions for setup and operation. Additionally, choose a seamer that is easy to clean and maintain, as regular maintenance is essential for ensuring optimal performance and prolonging the lifespan of the equipment.

When selecting a high-quality dual head beverage can seamer, it is also important to consider the size and compatibility of the equipment with your existing production line. Make sure that the seamer is the right size for your production space and can be easily integrated into your existing workflow. Additionally, check the compatibility of the seamer with the size and type of cans that you will be sealing to ensure a perfect seal every time.

Finally, consider the cost and overall value of the seamer. While it is important to invest in a high-quality seamer that meets your business needs, it is also important to consider your budget and the overall return on investment. Compare the features, performance, and durability of different seamers to find the best value for your money.

In conclusion, choosing the right high-quality dual head beverage can seamer for your business is a crucial decision that can impact the efficiency and quality of your production process. Consider factors such as speed, durability, ease of operation, compatibility, and cost when selecting a seamer that meets your business needs. By taking the time to research and compare different options, you can find a seamer that will help you seal your beverages with precision and efficiency, ensuring customer satisfaction and success for your business.

Maintenance Tips for Ensuring Longevity of Your High Quality Dual Head Beverage Can Seamer

Maintaining a high-quality dual head beverage can seamer is essential to ensure its longevity and optimal performance. Regular maintenance not only extends the lifespan of the machine but also helps prevent costly repairs and downtime. In this article, we will discuss some key maintenance tips to help you keep your dual head beverage can seamer in top condition.

First and foremost, it is important to regularly clean and sanitize your dual head beverage can seamer. This will help prevent the buildup of dirt, debris, and bacteria that can affect the machine’s performance and the quality of the sealed cans. Use a mild detergent and warm water to clean the exterior and interior of the seamer, paying special attention to the seams and crevices where dirt can accumulate. Be sure to rinse thoroughly and sanitize with a food-safe sanitizer to ensure the machine is free from harmful bacteria.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear and tear. Check the seals, gaskets, and moving parts for any damage or deterioration. Replace any worn or damaged parts immediately to prevent leaks and ensure a tight seal on the cans. Regularly lubricate the moving parts of the seamer to reduce friction and prevent premature wear. Use a food-grade lubricant recommended by the manufacturer to ensure compatibility with the machine’s components.

Another important maintenance tip is to calibrate the seamer regularly to ensure it is operating at the correct settings. Over time, the machine may drift out of alignment, leading to improper sealing and potential leaks. Follow the manufacturer’s guidelines for calibrating the seamer, and make any necessary adjustments to ensure it is sealing the cans properly. Regular calibration will help maintain the quality and consistency of the sealed cans, reducing the risk of product spoilage and waste.

It is also important to keep the surrounding area clean and free from clutter to prevent accidents and ensure safe operation of the seamer. Remove any debris, spills, or obstructions that could interfere with the machine’s operation. Keep the area around the seamer well-lit and ventilated to provide a safe working environment for operators. Regularly inspect the electrical connections and power supply to ensure they are in good condition and free from damage.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for your dual head beverage can seamer. This may include regular inspections, cleaning, lubrication, and calibration to keep the machine in optimal condition. Keep a record of all maintenance activities and repairs to track the machine’s performance and identify any recurring issues. By following these maintenance tips, you can ensure the longevity and reliability of your high-quality dual head beverage can seamer, allowing you to produce consistently sealed cans with minimal downtime and waste.