- 27

- Dec

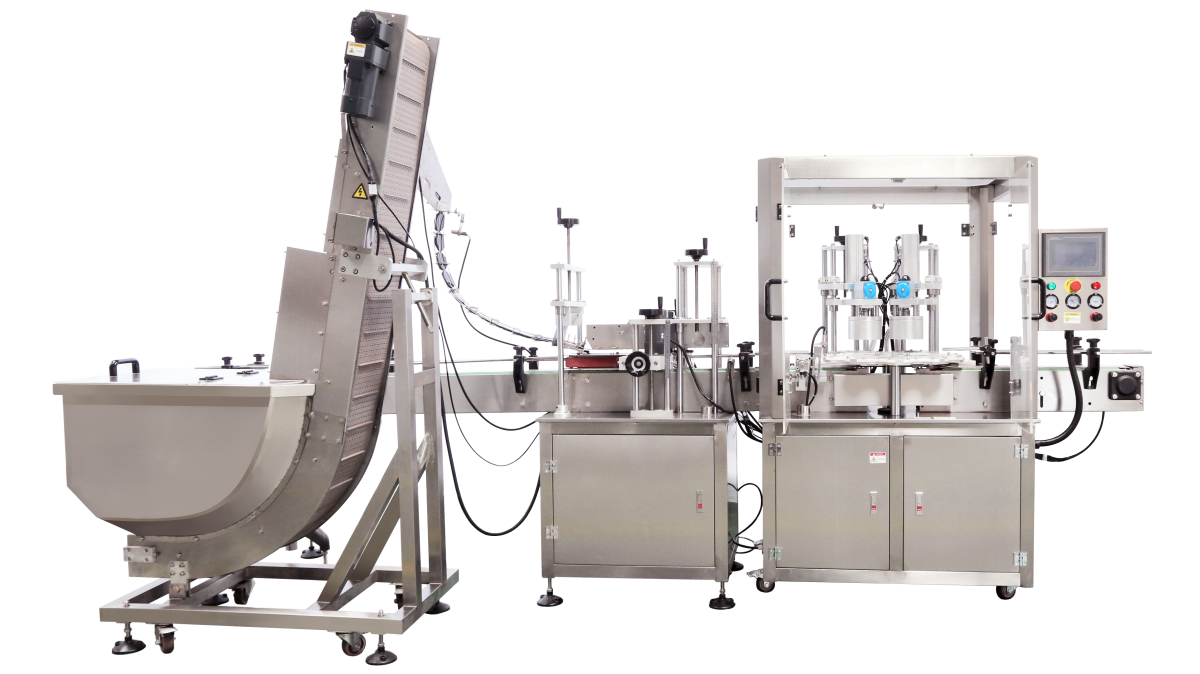

Vacuum Capping Machine,Jar Screw Vacuum Capper Equipment ,Bottle Vacuum Capping machine FVC30

Vacuum capping machine mostly use for glass bottle tinplate screw cap.It is widely used in food, medicine, cosmetics and other industries. It combines vacuum technology and capping technology to quickly and accurately complete the capping task, ensuring the sealing and safety of the product.

Vacuum capping machine remove bottle air oxidation and microbial contamination in the bottle, extend the shelf life of the product, and improve product quality and reliability.

Vacuum capping machine feature

1. It adopts automatic vacuum screw cap sealing in one, high degree of automation

2.It’s used for various shape of glass bottle with tin lid filling seasoning sauce,pickles,jam,sauce,canned fruit .

3.The appearance structure of the whole machine is stainless steel, which has good performance, easy operation and beautiful appearance.

4.It has the functions of vacuum screw cap and ordinary cap screw cap,compatible with three bayonet caps and four bayonet caps.

Machine Paremeter

Number of capping heads: 2

Capping speed: 25-34pcs/min

Adapt to bottle height: 50-180mm

Applicable bottle diameter: ¢30-¢150mm

Vacuum in the bottle: -0.04- -0.07MPA

Screw cap torque: 5-15N.M

Voltage: AC 220V 50Hz

Total power: <2.5KW

Working pressure (compressed air): ≥0.4MPa

Air consumption: about 0.3 cubic/min

The vacuum capping machine is suitable for all products that use glass screw-mouth bottle caps and standard tinplate claw-type screw-open caps, such as condiments, canned seafood, canned fruits, canned vegetables, soy products, etc., especially canned products that require reliable vacuum packaging and high temperature and high pressure sterilization.