- 20

- Mar

Sealing machine working principle

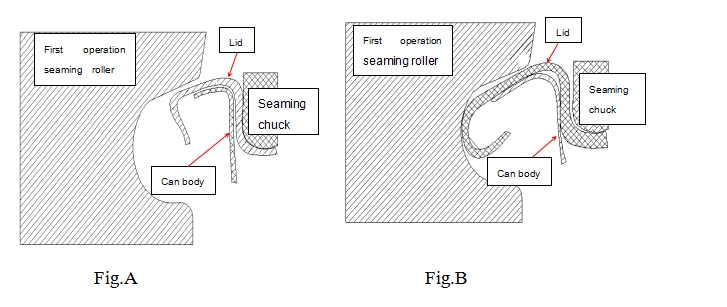

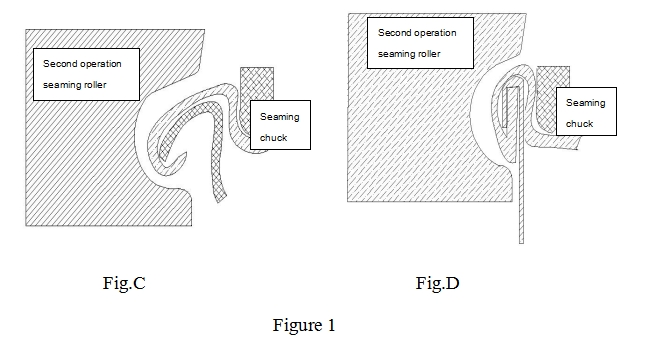

Can sealing machine adopts the double-winding principle, the sealing effect is achieved by the step of folding and flattening the edge of the lid and the can. The formation steps are as follows:

1.The first operation seaming roller, when the can body and can lid enter to under the sealing head , the lower tray rises, at the same time, the can lid is fitted to the pressure by the vertical applied seaming chuck.

2.Then the first operation seaming roller starts to be rolled around the can body and around the can lid. During this process. The flange of the can body will bend downwards, as shown in Fig A. The side hook of the can is formed, and the edge of the can lid is bent downward as shown in Fig. B, then folded along the end of the hook side of the can to the inner side thereof to form a can lid hook. Thus, a hemming formed by the can body and the can lid is formed. As shown in Fig C.

3.After the first operation is completed, the second operation seaming roller is pushed forward, and the curl formed by the first operation is pressed and flattened to remove the wrinkles of the curl to make it smoother, and the sealing compound is utilized. The gap in the folded layer is completely filled to form a gas-tight sealing bead, and the sealing work is completed as shown in Fig.D

4.The tray is turned down and the sealed can is taken away from the seaming chuck. The formation steps are shown in Figure 1.