- 08

- Dec

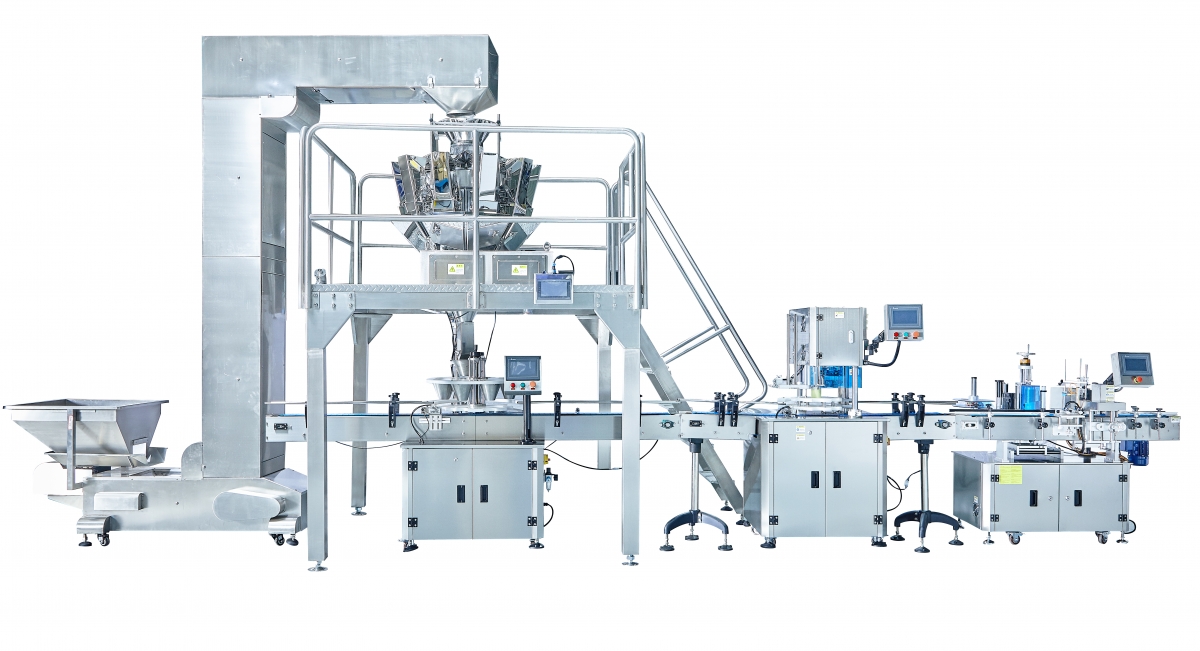

Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Benefits of Using Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are revolutionizing the way companies package and distribute their products. These machines offer a wide range of benefits that can help businesses increase efficiency, reduce waste, and improve overall productivity.

One of the key benefits of using an automatic weighing filling line machine is the accuracy it provides. These machines are equipped with advanced technology that ensures precise measurements of nuts, beans, cashews, and other products. This level of accuracy is crucial for companies that need to meet strict quality control standards and ensure that their products are consistently packaged in the correct quantities.

In addition to accuracy, automatic weighing filling line machines also offer speed and efficiency. These machines are capable of filling and packaging products at a much faster rate than manual methods, allowing companies to increase their output and meet customer demand more effectively. This increased efficiency can lead to cost savings and improved profitability for businesses in the long run.

Another benefit of using an automatic weighing filling line machine is the reduction of waste. By accurately measuring and filling products, these machines help companies minimize overfilling and underfilling, which can result in significant waste over time. This not only saves money for businesses but also helps reduce their environmental impact by decreasing the amount of product that ends up in landfills.

Furthermore, automatic weighing filling line machines are designed to be user-friendly and easy to operate. This makes it simple for companies to train their employees on how to use the machines effectively, reducing the risk of errors and ensuring consistent results. Additionally, many of these machines are equipped with features such as touch screens and programmable settings, making it easy for operators to adjust settings and customize the machine to meet their specific needs.

One of the most significant benefits of using an automatic weighing filling line machine is the improved overall productivity it provides. By streamlining the packaging process and reducing the time it takes to fill and package products, these machines allow companies to increase their output and meet customer demand more efficiently. This can help businesses grow and expand their operations while maintaining high levels of quality and consistency.

In conclusion, automatic weighing filling line machines offer a wide range of benefits for companies that package nuts, beans, cashews, and other products. From increased accuracy and efficiency to reduced waste and improved productivity, these machines can help businesses streamline their operations and achieve greater success in the marketplace. By investing in an automatic weighing filling line machine, companies can position themselves for long-term growth and profitability in the competitive packaging industry.

How to Choose the Right Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine for Your Business

When it comes to packaging products like nuts, beans, cashews, and cans, having an efficient weighing and filling line machine is essential for any business. These machines can help streamline the packaging process, increase productivity, and ensure accurate measurements for each product. However, with so many options available on the market, choosing the right automatic nuts beans cashew cans weighing filling line machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting the best machine for your needs.

One of the first things to consider when choosing an automatic weighing and filling line machine is the type of products you will be packaging. Different machines are designed to handle specific types of products, so it is important to choose a machine that is suitable for the size, shape, and weight of the items you will be packaging. For example, if you will be packaging small nuts and beans, you may need a machine with a high level of precision and accuracy. On the other hand, if you will be packaging larger items like cans, you may need a machine with a higher capacity and faster filling speed.

Another important factor to consider is the speed and efficiency of the machine. Depending on the volume of products you will be packaging, you may need a machine that can fill and weigh a large number of items quickly and accurately. Look for machines that have a high filling speed and can handle a wide range of product sizes to ensure maximum efficiency in your packaging process.

In addition to speed and efficiency, it is also important to consider the accuracy of the machine. Accurate measurements are crucial for ensuring that each product is packaged correctly and that you are not wasting any materials. Look for machines that have built-in sensors and technology to ensure precise weighing and filling of each item.

When choosing an automatic weighing and filling line machine, it is also important to consider the overall size and footprint of the machine. Make sure that the machine will fit comfortably in your production space and that it is easy to operate and maintain. Look for machines that are user-friendly and come with clear instructions and support from the manufacturer.

Finally, consider the cost of the machine and your budget. Automatic weighing and filling line machines can vary greatly in price depending on their features and capabilities. It is important to choose a machine that fits within your budget while still meeting your needs for speed, accuracy, and efficiency.

In conclusion, choosing the right automatic nuts beans cashew cans weighing filling line machine for your business is a crucial decision that can have a significant impact on your packaging process. Consider factors such as the type of products you will be packaging, the speed and efficiency of the machine, accuracy, size, and cost when making your decision. By taking the time to research and evaluate your options, you can find a machine that will help streamline your packaging process and improve the overall efficiency of your business.

Maintenance Tips for Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.