- 08

- Dec

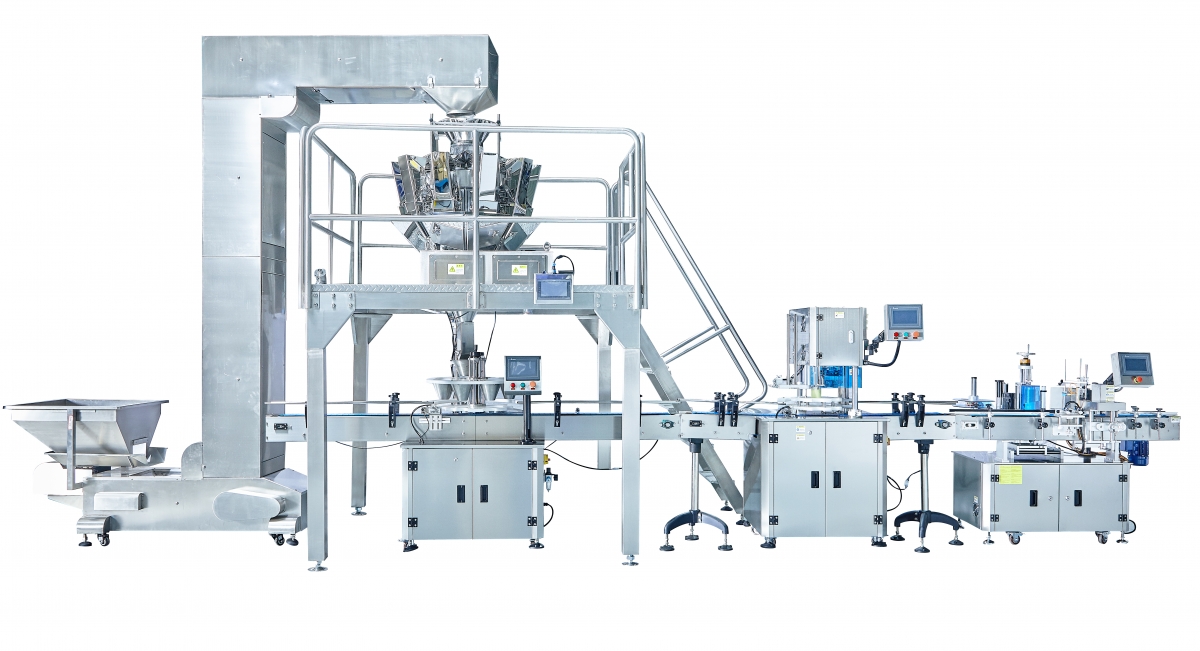

Tsarin Kwaya Ta atomatik Wake Cashew Gwangwani Ma’aunin Layin Cika Na’ura

Amfanin Amfani da Kwayoyi Ta atomatik Wake Cashew Gwangwani Ma’aunin Cika Layin Na’ura

Akwai gwangwani ta atomatik gwangwani cashew gwangwani masu auna injunan layi suna canza yadda kamfanoni ke tattarawa da rarraba kayayyakinsu. Waɗannan injunan suna ba da fa’idodi da yawa waɗanda za su iya taimaka wa kasuwanci haɓaka haɓaka aiki, rage sharar gida, da haɓaka yawan aiki gabaɗaya.

Daya daga cikin mahimman fa’idodin amfani da injin auna ma’aunin layukan atomatik shine daidaiton da yake bayarwa. Waɗannan injunan suna da ingantattun fasaha waɗanda ke tabbatar da ma’aunin goro, wake, cashews, da sauran samfuran. Wannan matakin daidaito yana da mahimmanci ga kamfanoni waɗanda ke buƙatar cika ƙayyadaddun ƙa’idodin sarrafa inganci da tabbatar da cewa samfuran su ana tattara su akai-akai a cikin adadi daidai.

Bugu da ƙari, daidaito, injina na atomatik cike da layin suna kuma ba da sauri da inganci. Waɗannan injunan suna da ikon cikawa da tattara samfuran cikin sauri fiye da hanyoyin hannu, suna ba kamfanoni damar haɓaka kayan aikin su da biyan buƙatun abokin ciniki yadda ya kamata. Wannan haɓakar haɓakawa na iya haifar da tanadin farashi da ingantacciyar riba ga kasuwanci a cikin dogon lokaci.

Ta hanyar aunawa daidai da cika samfuran, waɗannan injina suna taimaka wa kamfanoni rage yawan cikawa da cikawa, wanda zai iya haifar da ɓata mai yawa akan lokaci. Wannan ba wai kawai yana adana kuɗi don kasuwanci ba har ma yana taimakawa rage tasirin muhalli ta hanyar rage adadin samfuran da ke ƙarewa a cikin wuraren sharar ƙasa.

Wannan ya sa ya zama mai sauƙi ga kamfanoni su horar da ma’aikatan su yadda za su yi amfani da na’urori yadda ya kamata, rage haɗarin kurakurai da kuma tabbatar da daidaiton sakamako. Bugu da ƙari, da yawa daga cikin waɗannan injinan suna da fasali irin su allon taɓawa da saitunan shirye-shirye, yana sauƙaƙa wa masu aiki don daidaita saitunan da keɓance injin don biyan takamaiman bukatunsu.

Injin layi shine ingantattun kayan aikin da yake bayarwa. Ta hanyar daidaita tsarin marufi da rage lokacin da ake buƙata don cikawa da haɗa samfuran, waɗannan injunan suna ba wa kamfanoni damar haɓaka kayan aikin su da biyan buƙatun abokin ciniki yadda ya kamata. Wannan na iya taimaka wa ‘yan kasuwa su haɓaka da faɗaɗa ayyukansu yayin da suke riƙe manyan matakan inganci da daidaito.

A ƙarshe, injinan aunawa ta atomatik suna ba da fa’idodi da yawa ga kamfanoni waɗanda ke haɗa goro, wake, cashews, da sauran samfuran. Daga haɓaka daidaito da inganci zuwa rage sharar gida da haɓaka aiki, waɗannan injunan na iya taimakawa kasuwancin daidaita ayyukansu da samun babban nasara a kasuwa. Ta hanyar saka hannun jari a cikin injin auna ma’aunin layin atomatik, kamfanoni za su iya sanya kansu don haɓaka na dogon lokaci da riba a cikin masana’antar shirya marufi.

Yadda ake Zaɓin Kwayar Kwayoyi Ta atomatik Wake Cashew Gwangwani Ma’aunin Layin Cika Inji don Kasuwancin ku

Lokacin zabar na’urar aunawa ta atomatik da na’ura mai cikawa, yana da mahimmanci kuma a yi la’akari da girman gaba ɗaya da sawun injin ɗin. Tabbatar cewa injin zai dace da kwanciyar hankali a cikin sararin samarwa kuma yana da sauƙin aiki da kulawa. Nemo injunan da suka dace da masu amfani kuma suna zuwa tare da bayyanannun umarni da tallafi daga masana’anta.

A ƙarshe, la’akari da farashin injin da kasafin kuɗin ku. Injin aunawa ta atomatik da injin layin cikewa na iya bambanta sosai cikin farashi dangane da fasalulluka da ƙarfin su. Yana da mahimmanci a zaɓi injin da ya dace da kasafin kuɗin ku yayin da kuke biyan bukatunku na sauri, daidaito, da inganci.

na iya yin tasiri mai mahimmanci akan tsarin marufi. Yi la’akari da abubuwa kamar nau’in samfuran da za ku yi marufi, saurin da ingancin injin, daidaito, girman, da farashi lokacin yanke shawarar ku. Ta hanyar ɗaukar lokaci don yin bincike da kimanta zaɓuɓɓukanku, zaku iya samun injin da zai taimaka daidaita tsarin marufi da haɓaka ingantaccen kasuwancin ku gaba ɗaya.

Nasihu na Kulawa don Kwayoyi Ta atomatik Wake Cashew Gwangwani Mai Auna Cika Layin Injin

Akwai gwangwani ta atomatik wake gwangwani cashew gwangwani masu auna injin layi kayan aiki ne masu mahimmanci a masana’antar sarrafa abinci. An ƙera waɗannan injunan don auna daidai da cika nau’ikan goro, wake, da cashews cikin gwangwani, tabbatar da daidaiton ingancin samfur da rage aikin hannu. Don tabbatar da ingantaccen aiki na waɗannan injuna da hana lalacewa, kulawa na yau da kullun yana da mahimmanci. A cikin wannan labarin, za mu tattauna wasu shawarwarin kulawa don ƙwayar ƙwaya ta atomatik wake gwangwani cashew gwangwani masu auna injin layin cikawa.

Daya daga cikin mahimman ayyukan kula da waɗannan injinan shine tsaftacewa akai-akai. A tsawon lokaci, ƙura, tarkace, da barbashi na abinci na iya taruwa akan kayan aikin injin, wanda ke haifar da raguwar inganci da yuwuwar rashin aiki. Ana ba da shawarar tsaftace na’ura bayan kowane amfani, ba da kulawa ta musamman ga hanyoyin aunawa da cikawa, da bel ɗin jigilar kaya da firikwensin. Yi amfani da goga mai laushi ko kyalle don cire duk wani abu da aka gina kuma a tabbatar da cewa dukkan sassan sun bushe kafin a sake sarrafa na’ura. Bincika sako-sako da kusoshi ko skru, lalatar bel na isar da sako, da na’urori masu armashi da suka lalace. Sauya duk wani abu da ya lalace ko ya lalace nan da nan don hana lalacewar na’urar da tabbatar da ci gaba da aiki. Har ila yau yana da kyau a rika shafawa a sassa masu motsi, kamar gears da bearings, don rage juzu’i da tsawaita tsawon rayuwar na’ura. Tsawon lokaci, hanyoyin aunawa da na’ura na na’ura na iya zama mara kyau, wanda zai haifar da ingantattun ma’auni da rashin daidaiton ingancin samfur. Don tabbatar da ingantaccen aunawa da cikowa, daidaita injin bisa ga umarnin masana’anta. Wannan na iya haɗawa da daidaita saituna akan panel ɗin sarrafawa ko yin amfani da ma’aunin daidaitawa don tabbatar da daidaiton injin. Bincika wayoyi, masu haɗawa, da kwamitin kulawa don kowane alamun lalacewa ko lalata. Sake-saken haɗin kai ko maras kyaun wayoyi na iya haifar da rashin aikin lantarki da haifar da haɗari. Idan kun lura da kowace matsala tare da kayan aikin lantarki, tuntuɓi ƙwararren ƙwararren masani don gyarawa ko musanya su.

Wannan na iya haɗawa da dubawa lokaci-lokaci, tsaftacewa, lubrication, da ayyukan daidaitawa. Ta hanyar bin ƙa’idodin masana’anta, zaku iya tabbatar da cewa injin yana aiki yadda yakamata kuma amintacce, yana rage haɗarin lalacewa da gyare-gyare masu tsada.

A ƙarshe, kiyayewa na yau da kullun yana da mahimmanci don ingantaccen aiki na ƙwaya ta atomatik wake cashew gwangwani masu auna injin ciko. Ta bin waɗannan shawarwarin kulawa, za ku iya tsawaita rayuwar injin, tabbatar da daidaiton awo da cikowa, da hana ɓarna mai tsada. Ka tuna tsaftace na’ura akai-akai, bincika lalacewa da tsagewa, daidaita injin, duba kayan aikin lantarki, da kuma bi tsarin kulawa na masana’anta. Tare da kulawar da ta dace, ƙwayayen ku ta atomatik wake gwangwani cashew gwangwani masu yin layukan cika injin za su ci gaba da aiki cikin sauƙi da inganci, yana taimaka muku cimma burin samar da ku.

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.