- 08

- Dec

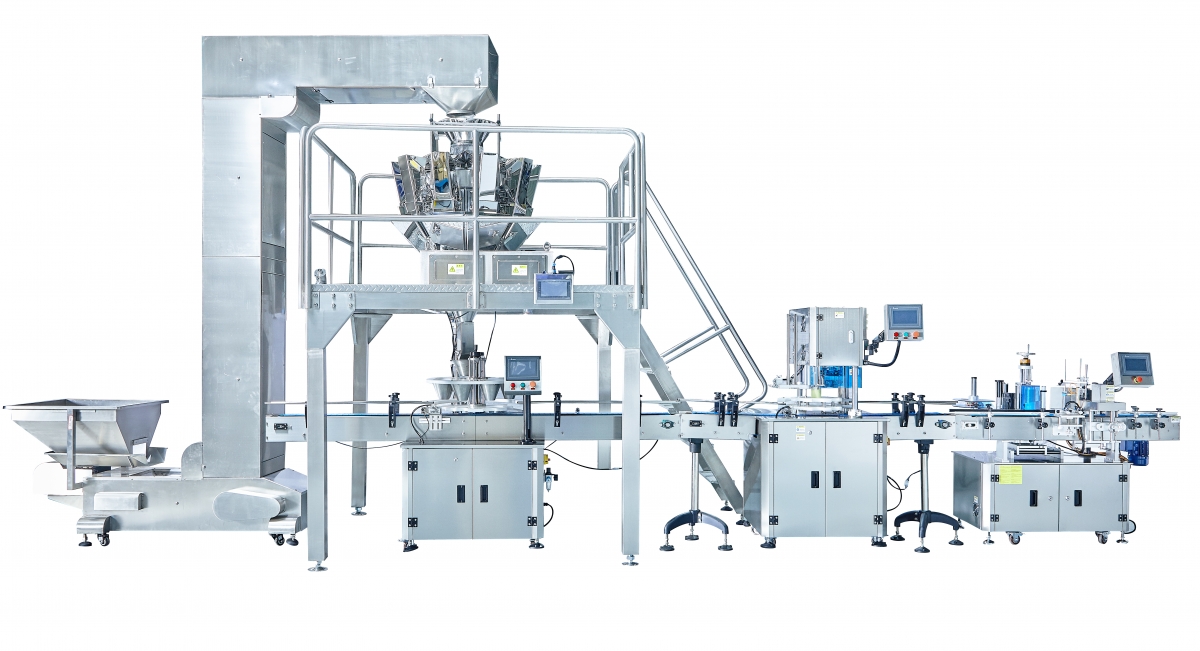

Mashine ya Kujaza Mizani ya Kujaza Mizigo ya Karanga Kopo za Korosho

Faida za Kutumia Mashine ya Kujaza Mizani ya Kujaza Mizigo ya Karanga

Jinsi ya Kuchagua Mashine ya Kujaza Mizani ya Kujaza Mizani ya Karanga Kiotomatiki kwa Biashara Yako

Wakati wa kuchagua mashine ya kupimia na kujaza kiotomatiki, ni muhimu pia kuzingatia ukubwa wa jumla na alama ya miguu ya mashine. Hakikisha kuwa mashine itatoshea vizuri katika nafasi yako ya uzalishaji na kwamba ni rahisi kufanya kazi na kuitunza. Tafuta mashine ambazo zinafaa mtumiaji na uje na maagizo na usaidizi wazi kutoka kwa mtengenezaji.

Mwishowe, zingatia gharama ya mashine na bajeti yako. Mashine za kupimia na kujaza otomatiki zinaweza kutofautiana sana kwa bei kulingana na sifa na uwezo wao. Ni muhimu kuchagua mashine inayolingana na bajeti yako huku ukiendelea kukidhi mahitaji yako kwa kasi, usahihi na ufanisi.

Kwa kumalizia, kuchagua mikebe ya korosho ya maharagwe ya moja kwa moja yenye uzito wa mashine ya kujaza kwa ajili ya biashara yako ni uamuzi muhimu kwamba inaweza kuwa na athari kubwa kwenye mchakato wako wa ufungaji. Zingatia vipengele kama vile aina ya bidhaa utakazofunga, kasi na ufanisi wa mashine, usahihi, ukubwa na gharama unapofanya uamuzi wako. Kwa kuchukua muda wa kutafiti na kutathmini chaguo zako, unaweza kupata mashine ambayo itasaidia kurahisisha mchakato wako wa upakiaji na kuboresha ufanisi wa jumla wa biashara yako.

Vidokezo vya Matengenezo ya Mashine ya Kujaza Uzito ya Maharagwe ya Karanga

Mashine za kujaza korosho za karanga otomatiki ni nyenzo muhimu katika tasnia ya usindikaji wa chakula. Mashine hizi zimeundwa kupima na kujaza kwa usahihi aina mbalimbali za njugu, maharagwe na korosho kwenye makopo, kuhakikisha ubora wa bidhaa na kupunguza kazi ya mikono. Ili kuhakikisha uendeshaji mzuri wa mashine hizi na kuzuia kuharibika, matengenezo ya mara kwa mara ni muhimu. Katika makala haya, tutajadili baadhi ya vidokezo vya udumishaji wa makopo ya korosho ya maharagwe ya otomatiki yenye uzito wa mashine za kujaza.

Mojawapo ya kazi muhimu zaidi za matengenezo ya mashine hizi ni kusafisha mara kwa mara. Baada ya muda, vumbi, uchafu na chembe za chakula zinaweza kujilimbikiza kwenye vipengele vya mashine, na hivyo kusababisha kupungua kwa ufanisi na utendakazi unaowezekana. Inashauriwa kusafisha mashine baada ya kila matumizi, kulipa kipaumbele maalum kwa taratibu za kupima na kujaza, pamoja na mikanda ya conveyor na sensorer. Tumia brashi au kitambaa laini kuondoa mrundikano wowote na uhakikishe kuwa sehemu zote zimekauka kabla ya kuendesha mashine tena.

Mbali na kusafisha, ni muhimu kukagua mashine mara kwa mara ikiwa kuna dalili zozote za kuchakaa na kuchakaa. Angalia bolt au skrubu zilizolegea, mikanda ya kupitisha mizigo iliyoharibika na vitambuzi vilivyochakaa. Badilisha sehemu zilizoharibiwa au zilizovaliwa mara moja ili kuzuia uharibifu zaidi kwa mashine na uhakikishe kuwa unaendelea kufanya kazi. Pia ni wazo nzuri kulainisha sehemu zinazosonga, kama vile gia na fani, ili kupunguza msuguano na kupanua maisha ya mashine.

Kurekebisha mashine ni kazi nyingine muhimu ya matengenezo ambayo inapaswa kufanywa mara kwa mara. Baada ya muda, mitambo ya kupima uzito na kujaza inaweza kupotoshwa, na kusababisha vipimo visivyo sahihi na ubora wa bidhaa usiolingana. Ili kuhakikisha uzani sahihi na kujaza, rekebisha mashine kulingana na maagizo ya mtengenezaji. Hii inaweza kuhusisha kurekebisha mipangilio kwenye paneli dhibiti au kutumia vipimo vya urekebishaji ili kuthibitisha usahihi wa mashine.

Kukagua mara kwa mara vipengele vya umeme vya mashine pia ni muhimu kwa utendakazi wake ufaao. Kagua nyaya, viunganishi na paneli dhibiti kwa dalili zozote za uharibifu au kutu. Viunganishi vilivyolegea au nyaya zenye hitilafu zinaweza kusababisha hitilafu za umeme na kusababisha hatari ya usalama. Ukigundua matatizo yoyote ya vifaa vya umeme, wasiliana na fundi aliyehitimu kuvirekebisha au kuvibadilisha. Hii inaweza kujumuisha ukaguzi wa mara kwa mara, kusafisha, kulainisha, na kazi za urekebishaji. Kwa kufuata miongozo ya mtengenezaji, unaweza kuhakikisha kwamba mashine inafanya kazi kwa ufanisi na kwa uhakika, na kupunguza hatari ya kuharibika na matengenezo ya gharama kubwa.

Kwa kumalizia, matengenezo ya mara kwa mara ni muhimu kwa utendakazi mzuri wa makopo ya korosho ya maharagwe ya moja kwa moja yenye uzito wa mashine za kujaza. Kwa kufuata vidokezo hivi vya urekebishaji, unaweza kuongeza muda wa maisha wa mashine, kuhakikisha uzani na kujaza kwa usahihi, na kuzuia kuharibika kwa gharama kubwa. Kumbuka kusafisha mashine mara kwa mara, kukagua ikiwa imechakaa, kusawazisha mashine, angalia vifaa vya umeme, na ufuate ratiba ya matengenezo ya mtengenezaji. Ukiwa na utunzaji mzuri, makopo yako ya korosho ya kiotomatiki yenye uzani wa kujaza uzito yataendelea kufanya kazi vizuri na kwa ufanisi, kukusaidia kufikia malengo yako ya uzalishaji.

Maintenance Tips for Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.