- 08

- Dec

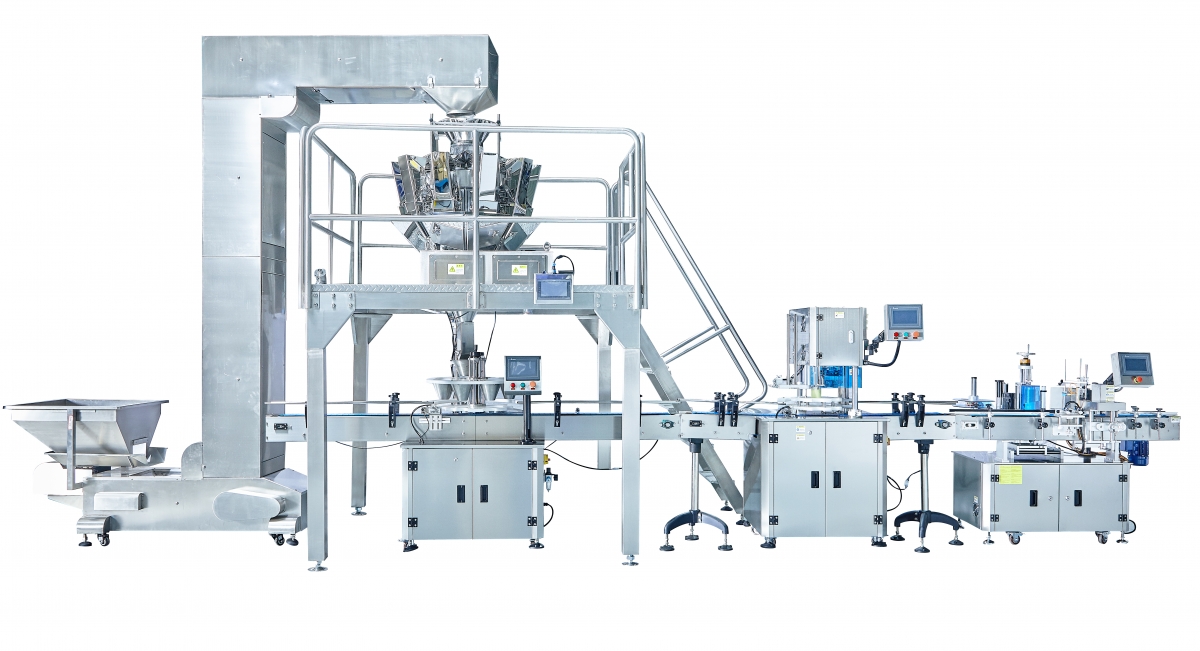

Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Melemo ea ho sebelisa Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Mokhoa oa ho Khetha Mochini oa ho Tlatsa Lithako tsa Linaoa tsa Li-Cashew tse nepahetseng bakeng sa Khoebo ea Hao

Malebela a Tlhokomelo bakeng sa Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Mechini ea li-cashew tsa linaoa tsa linaoa tse itšebetsang tse boima ba mochini oa ho tlatsa ke lisebelisoa tsa bohlokoa indastering ea ho lokisa lijo. Mechini ena e etselitsoe ho lekanya ka nepo le ho tlatsa mefuta e fapaneng ea linate, linaoa le li-cashews ka makotikoti, ho netefatsa boleng bo tsitsitseng ba sehlahisoa le ho fokotsa mosebetsi oa matsoho. Ho etsa bonnete ba hore mechine ena e sebetsa ka thelelo le ho thibela ho robeha, ho hlokomeloa kamehla ho bohlokoa. Sehloohong sena, re tla tšohla malebela a tlhokomelo bakeng sa makotikoti a cashew a linaoa a othomathiki a linaoa tse boima ba mochini o tlatsang mochini.

E ‘ngoe ea mesebetsi ea bohlokoa ka ho fetesisa ea ho lokisa mechini ena ke ho hloekisa khafetsa. Ha nako e ntse e ea, lerōle, lithōle le likaroloana tsa lijo li ka bokellana likarolong tsa mochine, e leng se lebisang ho fokotseng ho sebetsa hantle le ho se sebetse hantle ho ka bang teng. Ho kgothaletswa ho hloekisa mochine ka mor’a tšebeliso e ‘ngoe le e’ ngoe, ho ela hloko ka ho khetheha mekhoa ea ho bekha le ho tlatsa, hammoho le mabanta a conveyor le li-sensor. Sebelisa borashe kapa lesela le bonolo ho tlosa ntho leha e le efe e hahang ‘me u netefatse hore likarolo tsohle li omme pele u sebelisa mochine hape.

Ho phaella tabeng ea ho hloekisa, ke habohlokoa hore kamehla u hlahlobe mochine bakeng sa matšoao leha e le afe a ho senyeha le ho taboha. Sheba hore na ha ho na liboutu kapa likurufu tse hlephileng, mabanta a conveyor a senyehileng, le lisensara tse tsofetseng. Kenya sebaka leha e le sefe se senyehileng kapa se tsofetseng hang-hang ho thibela tšenyo e eketsehileng mochineng le ho netefatsa hore o tsoela pele ho sebetsa. Hape ke mohopolo o motle ho tlotsa likarolo tse tsamaeang, joalo ka likere le li-bearings, ho fokotsa khohlano le ho lelefatsa bophelo ba mochini.

Ho lekanya mochini ke mosebetsi o mong oa bohlokoa oa tlhokomelo o lokelang ho etsoa khafetsa. Ha nako e ntse e ea, mekhoa ea ho bekha le ho tlatsa mochine e ka ‘na ea fetoha e sa nepahaleng, e lebisang ho litekanyo tse sa nepahalang le boleng bo sa tsitsang ba sehlahisoa. Ho etsa bonnete ba hore boima bo nepahetseng le ho tlatsa, lekanya mochini ho latela litaelo tsa moetsi. Sena se ka kenyelletsa ho lokisa li-setting tsa “control panel” kapa ho sebelisa litekanyo tsa boima ba ‘mele ho netefatsa ho nepahala ha mochini.

Ho hlahloba likarolo tsa motlakase tsa mochini khafetsa le hona ho bohlokoa bakeng sa ts’ebetso ea ona e nepahetseng. Lekola lithapo, lihokelo, le phanele ea taolo bakeng sa matšoao leha e le afe a tšenyo kapa ho bola. Lihokelo tse hlephileng kapa lithapo tse fosahetseng li ka baka ho se sebetse hantle ha motlakase ‘me tsa baka kotsi ea polokeho. Haeba u hlokomela mathata leha e le afe ka lisebelisoa tsa motlakase, ikopanye le setsebi se nang le tsebo ho li lokisa kapa ho li fetola.

Qetellong, ho bohlokoa ho latela kemiso e khothaletsoang ea moetsi bakeng sa makotikoti a cashew a linaoa a othomathiki a nang le boima ba mochini oa ho tlatsa. Sena se ka kenyelletsa tlhahlobo ea nako le nako, ho hloekisa, ho tlotsa, le mesebetsi ea ho lekanya. Ka ho latela tataiso ea moetsi, u ka etsa bonnete ba hore mochine o sebetsa ka mokhoa o nepahetseng le ka botšepehi, ho fokotsa kotsi ea ho senyeha le ho lokisoa ho theko e boima.

Qetellong, tlhokomelo ea kamehla ke ea bohlokoa bakeng sa ts’ebetso e nepahetseng ea linate tsa linaoa tsa cashew tsa cashew tse boima ba mechine ea ho tlatsa. Ka ho latela malebela ana a tlhokomelo, o ka lelefatsa bophelo ba mochini, oa etsa bonnete ba ho bekha le ho tlatsa ka nepo, ‘me oa thibela ho senyeha ho bitsang chelete e ngata. Hopola ho hloekisa mochine kamehla, ho hlahloba hore na ha ho na ho taboha le ho taboha, ho lekanya mochine, ho hlahloba likarolo tsa motlakase, le ho latela kemiso ea tlhokomelo ea moetsi. Ka tlhokomelo e nepahetseng, makotikoti a hau a linaoa a li-cashew a boima ba mochini oa ho tlatsa li tla tsoelapele ho sebetsa hantle le ka nepo, ho u thusa ho fihlela lipheo tsa hau tsa tlhahiso.

When choosing an automatic weighing and filling line machine, it is also important to consider the overall size and footprint of the machine. Make sure that the machine will fit comfortably in your production space and that it is easy to operate and maintain. Look for machines that are user-friendly and come with clear instructions and support from the manufacturer.

Finally, consider the cost of the machine and your budget. Automatic weighing and filling line machines can vary greatly in price depending on their features and capabilities. It is important to choose a machine that fits within your budget while still meeting your needs for speed, accuracy, and efficiency.

In conclusion, choosing the right automatic nuts beans cashew cans weighing filling line machine for your business is a crucial decision that can have a significant impact on your packaging process. Consider factors such as the type of products you will be packaging, the speed and efficiency of the machine, accuracy, size, and cost when making your decision. By taking the time to research and evaluate your options, you can find a machine that will help streamline your packaging process and improve the overall efficiency of your business.

Maintenance Tips for Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.