- 08

- Dec

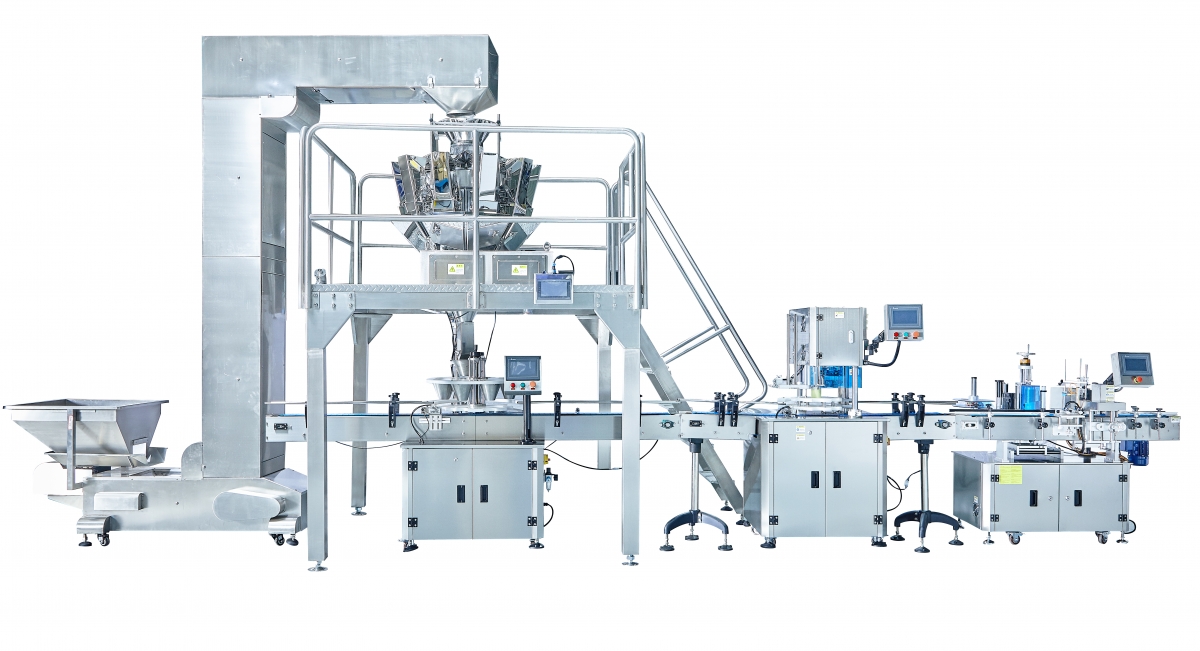

Akụkụ akpaaka agwa agwa Cashew Cans na-ejuputa igwe na-ejuputa akara

Uru nke Iji Ahịhịa akpaaka agwa Cashew Cans Weighing Filling Line Machine

Akụkụ akpaaka agwa agwa cashew Cans na-atụ igwe na-ejuputa ahịrị na-agbanwe ụzọ ụlọ ọrụ na-ebukọ ma kesaa ngwaahịa ha. Igwe ndị a na-enye ọtụtụ uru dị iche iche nwere ike inyere azụmaahịa aka ịbawanye arụmọrụ, belata mkpofu, ma melite nrụpụta mkpokọta.

Otu uru dị mkpa nke iji igwe na-ejuputa igwe na-ejuputa akpaaka bụ izi ezi ọ na-enye. Igwe ndị a nwere teknụzụ dị elu nke na-eme ka a hụ nha nke mkpụrụ, agwa, cashews na ngwaahịa ndị ọzọ. Ogo nke izi ezi a dị oké mkpa maka ụlọ ọrụ ndị chọrọ irubere ụkpụrụ njikwa mma siri ike ma hụ na a na-achịkọta ngwaahịa ha n’ụzọ ziri ezi.

Na mgbakwunye na izi ezi, igwe na-ejuputa akara akpaaka na-enyekwa ọsọ na arụmọrụ. Igwe ndị a nwere ike ijuputa na nkwakọ ngwaahịa na ngwa ngwa ngwa ngwa karịa ụzọ ntuziaka, na-enye ohere ka ụlọ ọrụ na-abawanye mmepụta ha ma na-egbo mkpa ndị ahịa nke ọma. Nke a na-abawanye arụmọrụ nwere ike iduga n’ịkwakọba ọnụ ahịa yana ịbawanye uru maka azụmaahịa n’ikpeazụ.

Uru ọzọ dị na iji igwe na-ejuputa igwe na-ejuputa akpaka bụ mbelata ihe mkpofu. Site n’ịtụ ma na-ejuputa ngwaahịa n’ụzọ ziri ezi, igwe ndị a na-enyere ụlọ ọrụ aka ibelata njupụta na imeju, nke nwere ike ịkpata nnukwu n’efu ka oge na-aga. Ọ bụghị nanị na nke a na-azọpụta ego maka achụmnta ego kamakwa ọ na-enye aka ibelata mmetụta gburugburu ebe obibi ha site n’ịbelata ọnụ ọgụgụ nke ngwaahịa na-ejedebe n’ime ebe a na-ekpofu ahịhịa.

Ọzọkwa, a haziri igwe na-ejuputa igwe na-atụnye akpaaka ka ọ bụrụ enyi na enyi yana mfe ịrụ ọrụ. Nke a na-eme ka ọ dị mfe maka ụlọ ọrụ ịzụ ndị ọrụ ha ka ha si eji igwe arụ ọrụ nke ọma, na-ebelata ihe ize ndụ nke njehie ma hụ na nsonaazụ na-agbanwe agbanwe. Ọzọkwa, ọtụtụ n’ime igwe ndị a nwere atụmatụ dị ka ihuenyo mmetụ na ntọala mmemme, na-eme ka ọ dịrị ndị na-arụ ọrụ mfe ịhazi ntọala na hazie igwe iji gboo mkpa ha kpọmkwem.

igwe ahịrị bụ arụpụta ọrụ zuru oke nke ọ na-enye. Site n’ịkwalite usoro nkwakọ ngwaahịa na ibelata oge ọ na-ewe iji jupụta na ngwugwu ngwaahịa, igwe ndị a na-enye ohere ka ụlọ ọrụ dịkwuo elu ma na-egbo mkpa ndị ahịa nke ọma. Nke a nwere ike inyere ụlọ ọrụ aka itolite ma gbasaa ọrụ ha ka ha na-ejigide ogo dị elu na ịdị n’otu.

N’ikpeazụ, igwe na-ejuputa akara akpaaka na-enye ọtụtụ uru maka ụlọ ọrụ na-ebukọta mkpụrụ, agwa, cashews na ngwaahịa ndị ọzọ. Site na ịba ụba nke ziri ezi na arụmọrụ ruo n’ibelata mkpofu na nrụpụta nrụpụta, igwe ndị a nwere ike inyere ndị azụmaahịa aka ịhazi ọrụ ha wee nweta nnukwu ihe ịga nke ọma n’ahịa. Site na itinye ego na igwe na-ejuputa igwe na-ejuputa akpaka, ụlọ ọrụ nwere ike idobe onwe ha maka uto ogologo oge na uru na ụlọ ọrụ nkwakọ ngwaahịa asọmpi.

Mgbe ị na-ahọrọ igwe na-atụnye akpaaka na ndochi, ọ dịkwa mkpa ịtụle nha na akara ukwu nke igwe. Jide n’aka na igwe ahụ ga-adaba nke ọma na oghere mmepụta gị nakwa na ọ dị mfe ịrụ ọrụ na ịnọgide na-enwe ya. Chọọ igwe ndị nwere enyi na enyi wee bịa na ntuziaka doro anya na nkwado sitere n’aka onye nrụpụta.

N’ikpeazụ, tụlee ego igwe na mmefu ego gị. Igwe eji atụ ihe na ndochi akpaaka nwere ike ịdịgasị iche na ọnụahịa dabere na njirimara na ike ha. Ọ dị mkpa ịhọrọ igwe dabara n’ime mmefu ego gị ka ị ka na-egbo mkpa gị maka ọsọ, izi ezi, na arụmọrụ.

nwere ike inwe mmetụta dị ukwuu na usoro nkwakọ ngwaahịa gị. Tụlee ihe ndị dị ka ụdị ngwaahịa ị ga-akwakọba, ọsọ na arụmọrụ nke igwe, izi ezi, nha, na ọnụ ahịa mgbe ị na-eme mkpebi gị. Site n’iwepụta oge iji nyochaa ma nyochaa nhọrọ gị, ị nwere ike ịchọta igwe nke ga-enyere aka ịhazi usoro nkwakọ ngwaahịa gị ma melite arụmọrụ azụmahịa gị n’ozuzu ya.

Ndụmọdụ maka mmezi akpaaka agwa agwa Cashew Cans Weighing Filling Line Machine

Akụkụ akpaaka agwa agwa cashew cans na-atụ igwe na-ejuputa ahịrị bụ akụrụngwa dị mkpa na ụlọ ọrụ nhazi nri. A haziri igwe ndị a iji tụọ ma mejupụta ụdị mkpụrụ, agwa na cashew dị iche iche n’ime mkpọ, na-ahụ na ịdị mma ngwaahịa na-agbanwe agbanwe yana ibelata ọrụ aka. Iji hụ na arụ ọrụ igwe ndị a na-arụ ọrụ nke ọma ma gbochie ndakpọ, mmezi mgbe niile dị oke mkpa. N’isiokwu a, anyị ga-atụle ụfọdụ ndụmọdụ maka mmezi akpaaka agwa agwa cashew cans na-atụnye igwe na-ejuputa akara.

Ka oge na-aga, uzuzu, irighiri ihe, na irighiri nri nwere ike ịgbakọta na akụrụngwa igwe, na-eduga n’ịrụ ọrụ mbelata yana enweghị ọrụ. A na-atụ aro ka ihicha igwe ahụ mgbe ejiri nke ọ bụla mee ihe, na-eleba anya n’ụzọ pụrụ iche na usoro nha na njuputa, yana eriri ebufe na sensọ. Jiri brush ma ọ bụ akwa dị nro wepụ ihe ọ bụla a na-ewuli elu wee hụ na akụkụ niile akpọọla nkụ tupu ị rụkwaa igwe ọzọ. Lelee maka bolts ma ọ bụ skru rụrụ arụ, eriri ebu mebiri emebi, na sensọ mebiela. Dochie akụkụ ọ bụla mebiri emebi ma ọ bụ eyi ozugbo iji gbochie mmebi igwe ọzọ wee hụ na ọ na-arụ ọrụ. Ọ dịkwa mma ite mmanụ ihe ndị na-akpụ akpụ, dị ka ngwo na bearings, iji belata esemokwu wee gbatịa ndụ igwe. Ka oge na-aga, usoro igwe na-atụ na ndochi nwere ike bụrụ nke na-ezighi ezi, na-ebute nha na-ezighi ezi yana ogo ngwaahịa na-ekwekọghị ekwekọ. Iji hụ na nha na njuputa ziri ezi, megharịa igwe dịka ntuziaka onye nrụpụta si dị. Nke a nwere ike ịgụnye ịhazigharị ntọala dị na panel njikwa ma ọ bụ iji igwe nrụzi iji chọpụta izi ezi nke igwe. Nyochaa wiring, njikọ, na panel njikwa maka akara ọ bụla nke mmebi ma ọ bụ corrosion ọ bụla. Njikọ ndị na-adịghị mma ma ọ bụ wiwi na-adịghị mma nwere ike ime ka ọkụ eletrik ghara ịrụ ọrụ ma nwee ihe ize ndụ nchekwa. Ọ bụrụ n’ịhụta nsogbu ọ bụla gbasara akụrụngwa eletrik, kpọtụrụ onye ọkachamara tozuru etozu ka ọ rụkwaa ma ọ bụ dochie ha. Nke a nwere ike ịgụnye nleba anya n’oge, ihicha, mmanu mmanu, na ọrụ nhazigharị. Site n’ịgbaso ntuziaka nke onye nrụpụta, ị nwere ike hụ na igwe na-arụ ọrụ nke ọma na ntụkwasị obi, na-ebelata ihe ize ndụ nke ndakpọ na nrụzi dị ọnụ ahịa.

N’ikpeazụ, nlekọta mgbe niile dị mkpa maka ịrụ ọrụ nke ọma nke mkpụrụ osisi akpaka agwa agwa cashew cans na-atụnye igwe na-ejuputa igwe. Site n’ịgbaso ndụmọdụ mmezi ndị a, ị nwere ike ịgbatị oge ndụ igwe ahụ, hụ na nha nha na njuputa ziri ezi, ma gbochie mmebi dị oke ọnụ. Cheta na ị na-ehicha igwe ahụ mgbe niile, nyochaa maka ike ya na ịdọka mmiri, mezie igwe ahụ, lelee akụrụngwa eletriki, ma soro usoro nhazi nke onye nrụpụta. Site na nrụzi kwesịrị ekwesị, mkpụrụ akụ gị akpaka agwa agwa cashew cans na-ejuputa igwe na-ejuputa igwe ga-aga n’ihu na-arụ ọrụ nke ọma na nke ọma, na-enyere gị aka iru ebumnuche mmepụta gị.

Maintenance Tips for Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.