- 08

- Dec

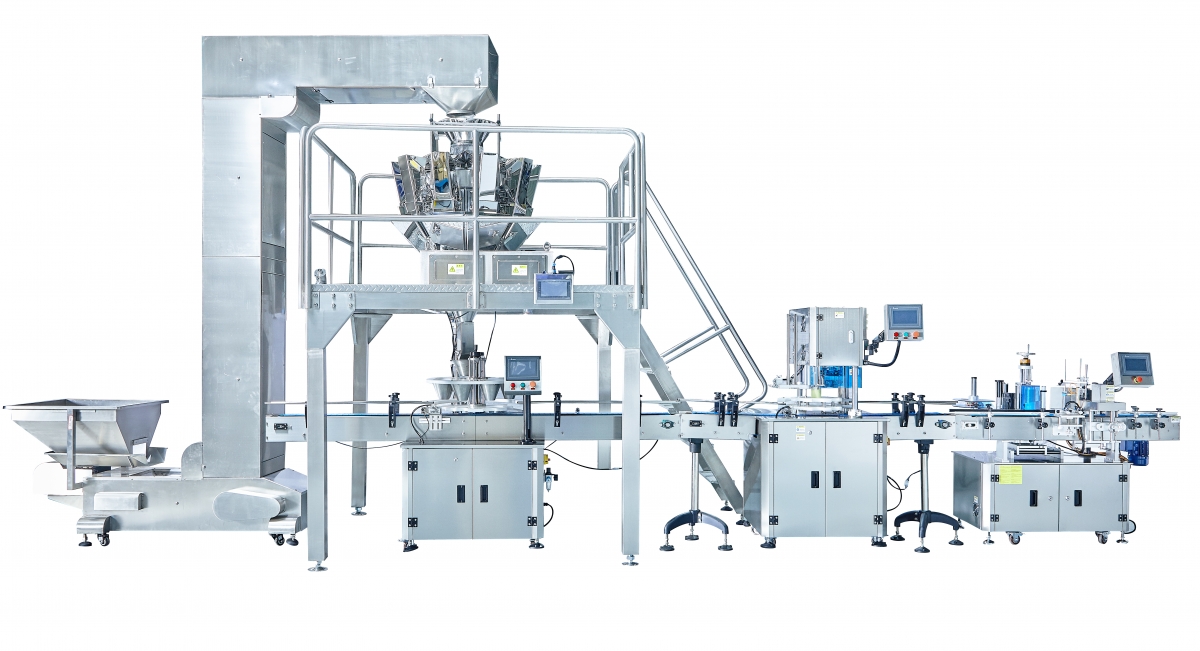

Masinina famenoana famenoana ny voanjo automatique

Masinina famenoana famenoana dia manova ny fomba famenoana sy fizarana ny vokatra ny orinasa. Ireo milina ireo dia manolotra tombontsoa maro isan-karazany izay afaka manampy ny orinasa hampitombo ny fahombiazany, hampihenana ny fako ary hanatsara ny vokatra amin’ny ankapobeny. Ireo milina ireo dia manana teknolojia avo lenta izay miantoka ny fandrefesana tsara ny voanjo, tsaramaso, cashews ary vokatra hafa. Ity haavon’ny fahitsiana ity dia zava-dehibe ho an’ny orinasa mila mahafeno ny fenitry ny fanaraha-maso ny kalitao ary miantoka fa ny vokatra dia voafono tsy tapaka amin’ny fatra marina. Ireo milina ireo dia afaka mameno sy mameno ny vokatra amin’ny tahan’ny haingana kokoa noho ny fomba manual, ahafahan’ny orinasa mampitombo ny vokatra sy mamaly ny fangatahan’ny mpanjifa amin’ny fomba mahomby kokoa. Io fitomboana mahomby io dia mety hitarika amin’ny fitsitsiana ny fandaniana sy ny tombom-barotra ho an’ny orinasa amin’ny fotoana maharitra. Amin’ny fandrefesana tsara sy famenoana vokatra, ireo milina ireo dia manampy ny orinasa hanamaivana ny famenoana be loatra sy tsy ampy, izay mety hiteraka fako be rehefa mandeha ny fotoana. Tsy vitan’ny mitahiry vola ho an’ny orinasa izany fa manampy amin’ny fampihenana ny fiantraikan’izy ireo amin’ny tontolo iainana amin’ny alàlan’ny fampihenana ny habetsahan’ny vokatra miafara amin’ny fanariam-pako. Izany dia manamora ny fanofanana ny mpiasany amin’ny fomba mahomby amin’ny fampiasana ireo milina ireo orinasa, mampihena ny mety hisian’ny fahadisoana ary miantoka ny vokatra tsy miovaova. Fanampin’izany, maro amin’ireo milina ireo no manana endri-javatra toy ny ecran touchy sy ny rindran-kira azo zahana, ka mahatonga ny mpampiasa ho mora ny manitsy ny toe-javatra sy manamboatra ny milina mifanaraka amin’ny filany manokana. milina tsipika no fanatsarana ny vokatra ankapobeny omeny. Amin’ny alàlan’ny fanamorana ny fizotran’ny fonosana sy ny fampihenana ny fotoana hamenoana sy famenoana vokatra, ireo milina ireo dia ahafahan’ny orinasa mampitombo ny vokatra ary mamaly ny fangatahan’ny mpanjifa amin’ny fomba mahomby kokoa. Afaka manampy ny orinasa hitombo sy hanitarana ny asany izany sady mitazona kalitao avo lenta sy tsy miovaova.

Ho fehin-kevitra, ny milina famenoana famenoana mandeha ho azy dia manome tombontsoa maro ho an’ireo orinasa mametaka voanjo, tsaramaso, cashews ary vokatra hafa. Avy amin’ny fampitomboana ny fahitsiana sy ny fahombiazany ka hatramin’ny fampihenana ny fako sy ny fampitomboana ny vokatra, ireo milina ireo dia afaka manampy ny orinasa hanatsara ny asany ary hahatratra fahombiazana bebe kokoa amin’ny tsena. Amin’ny alàlan’ny fampiasam-bola amin’ny milina famenoana famenoana mandeha ho azy, ny orinasa dia afaka mametraka ny tenany amin’ny fitomboana maharitra sy ny tombony amin’ny indostrian’ny fonosana mifaninana.

Ahoana ny fomba hifidianana ny milina famenoana famenoana ho an’ny orinasanao

Raha ny momba ny vokatra famonosana toy ny voanjo, tsaramaso, cashews ary kapoaka, dia ilaina amin’ny orinasa rehetra ny fananana milina famenoana sy famenoana mahomby. Ireo milina ireo dia afaka manampy amin’ny fanamorana ny fizotran’ny famonosana, mampitombo ny vokatra ary miantoka ny fandrefesana marina ho an’ny vokatra tsirairay. Na izany aza, miaraka amin’ny safidy maro azo eny an-tsena, ny fisafidianana ny tsara automatique tsaramaso tsaramaso cashew cans milanja milina famenoana tsipika ho an’ny orinasanao dia mety ho asa sarotra. Ato amin’ity lahatsoratra ity dia hiresaka momba ireo lafin-javatra lehibe tokony hodinihina isika rehefa mifidy milina tsara indrindra ho an’ny filanao. Ny milina samihafa dia natao hikarakarana karazana vokatra manokana, noho izany dia zava-dehibe ny mifidy milina mifanaraka amin’ny habeny, ny endriny ary ny lanjan’ny entana hofonosinao. Ohatra, raha hameno voanjo sy tsaramaso kely ianao, dia mety mila milina manana mari-pamantarana avo lenta sy marina ianao. Amin’ny lafiny iray, raha hameno entana lehibe kokoa toy ny kapoaka ianao, dia mety mila milina manana fahaiza-manao ambony kokoa sy haingana kokoa ny famenoana. Miankina amin’ny habetsahan’ny vokatra hofonosinao, dia mety mila milina afaka mameno sy mandanja entana marobe haingana sy marina ianao. Mitadiava milina manana hafainganam-pandeha feno famenoana ary mahazaka ny haben’ny vokatra isan-karazany mba hiantohana ny fahombiazana ambony indrindra amin’ny fizotran’ny fonosanao.

Ankoatra ny hafainganam-pandeha sy ny fahombiazany, dia zava-dehibe ihany koa ny mandinika ny fahamarinan’ny milina. Tena ilaina ny fandrefesana marina mba hahazoana antoka fa voafono tsara ny vokatra tsirairay ary tsy mandany fitaovana ianao. Mitadiava milina manana sensor sy teknolojia namboarina mba hiantohana ny fandanjana sy famenoana ny entana tsirairay.

Masinina famenoana famenoana automatique no fitaovana ilaina amin’ny indostrian’ny fanodinana sakafo. Ireo milina ireo dia natao handanja tsara sy hamenoana karazana voanjo, tsaramaso ary cashews isan-karazany ao anaty kapoaka, hiantohana ny kalitaon’ny vokatra tsy miovaova ary mampihena ny asa tanana. Mba hiantohana ny fampandehanana tsara ireo milina ireo sy hisorohana ny fahapotehana, dia zava-dehibe ny fikojakojana tsy tapaka. Ato amin’ity lahatsoratra ity dia hiresaka momba ny toro-hevitra momba ny fikojakojana ho an’ny voanjo mandeha ho azy tsaramaso cashew kapoaka milanja milina famenoana. Rehefa mandeha ny fotoana, ny vovoka, ny potipoti-javatra ary ny poti-tsakafo dia mety miangona eo amin’ny kojakoja ao amin’ilay milina, ka mihena ny fahombiazany sy ny mety ho tsy fahombiazany. Manoro hevitra ny hanadio ny milina aorian’ny fampiasana tsirairay, mandinika manokana ny mekanika lanja sy famenoana, ary koa ny fehikibo sy ny sensor. Mampiasà borosy na lamba malefaka mba hanesorana izay mety ho fananganana ary ho azo antoka fa maina daholo ny kojakoja rehetra alohan’ny hampandehanana ny milina indray.

Ankoatra ny fanadiovana dia ilaina ny manara-maso tsy tapaka ny milina raha misy soritr’aretina. Hamarino raha misy bolts na visy vaky, fehikibo conveyor simba, ary sensor efa tonta. Soloy avy hatrany izay kojakoja simba na tonta mba hisorohana ny fahasimbana bebe kokoa amin’ny milina ary hiantohana ny fitohizan’ny fiasan’izy io. Tsara ihany koa ny manosotra ny kojakoja mihetsika, toy ny kodiarana sy ny bearings, mba hampihenana ny fikorontanana sy hanitarana ny androm-piainan’ny milina.

Ny fanaovana calibration ny milina dia asa lehibe hafa fikojakojana izay tokony hatao tsy tapaka. Rehefa mandeha ny fotoana, ny mekanika lanja sy famenoana ny milina dia mety ho lasa tsy mifanaraka, ka miteraka fandrefesana tsy marina sy tsy mifanaraka amin’ny kalitaon’ny vokatra. Mba hahazoana antoka ny lanja sy ny famenoana marina, calibrate ny milina araka ny torolalan’ny mpanamboatra. Mety ho tafiditra ao anatin’izany ny fanitsiana ny fandrindrana eo amin’ny tontonana fanaraha-maso na ny fampiasana lanja fandrefesana mba hanamarinana ny fahamarinan’ilay milina. Jereo ny tariby, ny connecteur, ary ny tontonana fanaraha-maso raha misy famantarana misy fahasimbana na harafesina. Ny fifandraisana simba na ny tariby diso dia mety hiteraka tsy fahombiazan’ny herinaratra ary mety hampidi-doza. Raha mahatsikaritra olana amin’ny kojakoja elektrika ianao dia mifandraisa amin’ny teknisianina mahay hanamboatra na hanolo izany. Mety ho tafiditra ao anatin’izany ny fanaraha-maso tsindraindray, ny fanadiovana, ny fanosorana, ary ny asa calibration. Amin’ny fanarahana ny torolalan’ny mpanamboatra dia azonao antoka fa miasa tsara sy azo ianteherana ilay milina, mampihena ny mety hisian’ny fahasimbana sy ny fanamboarana lafo vidy. Amin’ny fanarahana ireo toro-hevitra momba ny fikojakojana ireo dia azonao atao ny manalava ny androm-piainan’ny milina, miantoka ny fandanjana sy ny famenoana marina, ary ny fisorohana ny fahapotehana lafo vidy. Aza hadino ny manadio tsy tapaka ny masinina, mandinika ny fahatapahan-jiro sy ny rovitra, manaova calibrate ny milina, manamarina ny singa elektrika, ary araho ny fandaharam-potoanan’ny mpanamboatra. Miaraka amin’ny fikojakojana araka ny tokony ho izy, ny milina famenoana famenoana voanjo mandeha ho azy dia mbola hiasa tsara sy mahomby, manampy anao hahatratra ny tanjonao amin’ny famokarana.

When choosing an automatic weighing and filling line machine, it is also important to consider the overall size and footprint of the machine. Make sure that the machine will fit comfortably in your production space and that it is easy to operate and maintain. Look for machines that are user-friendly and come with clear instructions and support from the manufacturer.

Finally, consider the cost of the machine and your budget. Automatic weighing and filling line machines can vary greatly in price depending on their features and capabilities. It is important to choose a machine that fits within your budget while still meeting your needs for speed, accuracy, and efficiency.

In conclusion, choosing the right automatic nuts beans cashew cans weighing filling line machine for your business is a crucial decision that can have a significant impact on your packaging process. Consider factors such as the type of products you will be packaging, the speed and efficiency of the machine, accuracy, size, and cost when making your decision. By taking the time to research and evaluate your options, you can find a machine that will help streamline your packaging process and improve the overall efficiency of your business.

Maintenance Tips for Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.