- 08

- Dec

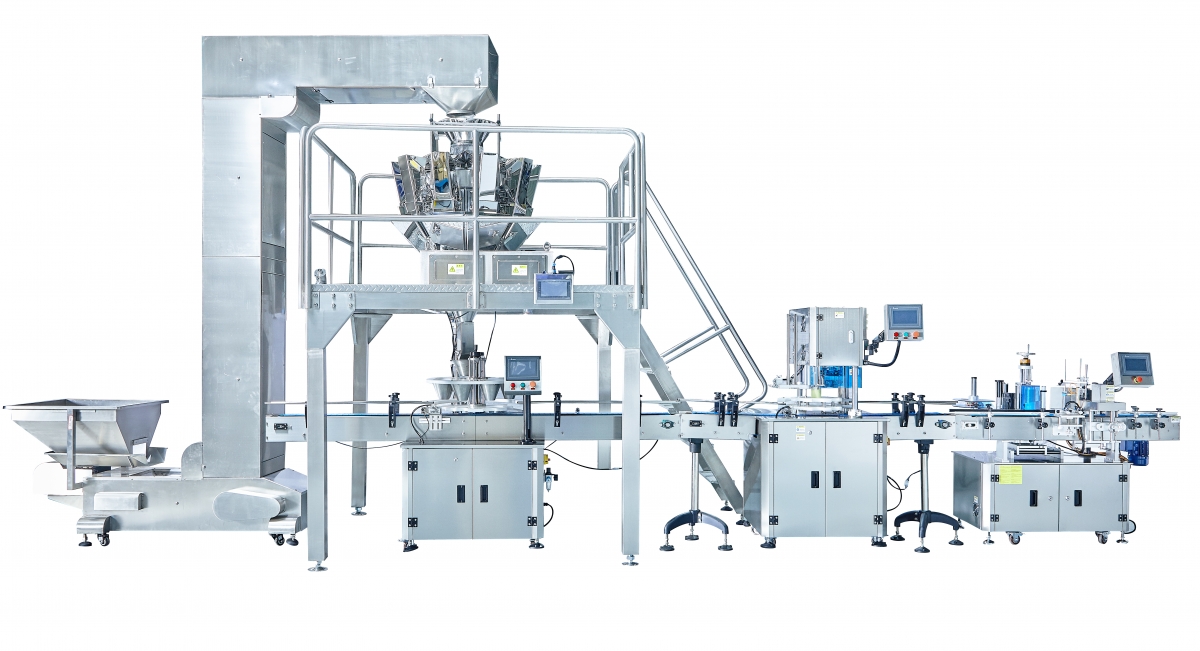

Automatic Nuts Beans Cashew Cans Weighing Kuzadza Line Machine

Benefits dzeKushandisa Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Maitiro eKusarudza Yakakodzera Otomatiki Nuts Beans Cashew Cans Inorema Kuzadza Line Machine yeBhizinesi Rako

Paunenge uchisarudza otomatiki kuyera uye yekuzadza mutsara muchina, zvakakoshawo kufunga nezvehukuru hwese uye tsoka yemuchina. Ita shuwa kuti muchina unokwana zvakanaka munzvimbo yako yekugadzira uye kuti iri nyore kushanda nekuchengetedza. Tsvaka michina iri nyore kushandisa uye uuye nemirayiridzo yakajeka uye rutsigiro kubva kumugadziri.

Pakupedzisira, funga nezve mutengo wemuchina uye bhajeti yako. Otomatiki kuyera uye yekuzadza mitsara michina inogona kusiyana zvakanyanya mumutengo zvichienderana nehunhu hwavo uye kugona kwavo. Izvo zvakakosha kuti usarudze muchina unokodzera mukati mebhajeti rako uchiri kusangana nezvido zvako zvekumhanya, kurongeka, uye kushanda nesimba.

Mukupedzisa, kusarudza chaiyo otomatiki nzungu bhinzi macashew magaba anoyera muchina wekuzadza mutsara webhizinesi rako isarudzo yakakosha kuti. inogona kuve nemhedzisiro yakakosha pane yako yekurongedza maitiro. Funga zvinhu zvakaita semhando yezvigadzirwa zvauchange uchirongedza, kumhanya uye kugona kwemuchina, huchokwadi, saizi, uye mutengo paunenge uchiita sarudzo yako. Nekutora nguva yekutsvagisa uye kuongorora sarudzo dzako, unogona kuwana muchina unozobatsira kukwenenzvera maitiro ako ekurongedza uye kuvandudza kushanda kwese kwebhizinesi rako.

Mazano ekuchengetedza eAutomatic Nuts Beans Cashew Cans Weighing Kuzadza Line Machine

Otomatiki nzungu bhinzi macashew magaba anorema ekuzadza mitsara michina yakakosha muindasitiri yekugadzira chikafu. Michina iyi yakagadzirirwa kunyatsoyera uye kuzadza mhando dzakasiyana dzenzungu, bhinzi, uye macashews mumagaba, kuve nechokwadi chekuenderana kwechigadzirwa uye kuderedza basa remaoko. Kuti uve nechokwadi chekushanda zvakanaka kwemichina iyi uye kudzivirira kuparara, kugadzirisa nguva dzose kwakakosha. Muchinyorwa chino, tichakurukura nezvemamwe matipi ekuchengetedza otomatiki nzungu bhinzi macashew magaba anorema ekuzadza michina michina.

Rimwe remabasa akanyanya kukosha ekugadzirisa michina iyi kuchenesa nguva dzose. Nekufamba kwenguva, guruva, marara, uye zvimedu zvechikafu zvinogona kuungana pazvikamu zvemuchina, zvichikonzera kudzikira kwehunyanzvi uye kusashanda zvakanaka. Inokurudzirwa kuchenesa muchina mushure mekushandisa kwega kwega, kubhadhara zvakanyanya kuyera uye kuzadza michina, pamwe nemabhandi ekutakura uye sensors. Shandisa bhurasho rakapfava kana kuti jira kubvisa chipi nechipi chaunga uye uone kuti zvikamu zvose zvaoma usati washandisa muchina wacho zvakare.

Kuwedzera pakuchenesa, zvakakosha kuti ugare uchiongorora muchina wacho kuona kana kusakara uye kubvaruka. Tarisa mabhaudhi asina kusimba kana screws, mabhandi ekutakura akakuvara, uye masensor asakara. Tsiva chero dzakakuvadzwa kana dzakasakara zvikamu nekukurumidza kudzivirira kumwe kukuvadzwa kumuchina uye kuve nechokwadi chekushanda kwayo. Ipfungwa yakanaka zvakare kuzora zvinhu zvinofamba zvakaita semagiya nemabearings, kuderedza kukwesha uye kuwedzera hupenyu hwemuchina.

Kugadzirisa muchina nderimwe basa rakakosha rekugadzirisa rinofanira kuitwa nguva nenguva. Nekufamba kwenguva, huremu hwemuchina nekuzadza huremu hunogona kuve husina kurongeka, zvichitungamira kune zviyero zvisina kurongeka uye kusawirirana kwemhando yechigadzirwa. Kuti uve nechokwadi chekuyera uye kuzadza kwakaringana, gadzirisa muchina unoenderana nemirairo yemugadziri. Izvi zvinogona kusanganisira kugadzirisa marongero epanera rekudzora kana kushandisa masimbi ekuyeresa kuratidza chokwadi chemuchina.

Kugara uchitarisa zvikamu zvemagetsi zvemuchina kwakakoshawo pakushanda kwayo. Ongorora wiring, zvinobatanidza, uye control panel kuona chero zviratidzo zvekukuvadzwa kana ngura. Lose connections kana tambo dzisina kunaka dzinogona kukonzera kusashanda kwemagetsi uye kuisa njodzi yekuchengetedza. Kana ukaona paine dambudziko nemidziyo yemagetsi, taura naana technician kuti azvigadzirise kana kuzvitsiva.

Chekupedzisira, zvakakosha kutevedzera zvakakurudzirwa nemugadziri wemagaba e-automatic nzungu bhinzi macashew anorema muchina wekuzadza. Izvi zvinogona kusanganisira kuongorora nguva nenguva, kuchenesa, kuisa mafuta, uye kugadzirisa mabasa. Nekutevera nhungamiro yemugadziri, unogona kuona kuti muchina unoshanda nemazvo uye nekuvimbika, uchidzikisa njodzi yekuputsika uye kugadzirisa kunodhura.

Pakupedzisira, kugadzirisa nguva dzose kwakakosha pakushanda kwakakodzera kweotomatiki nzungu bhinzi macashew cans anoyera mitsetse yekuzadza michina. Nekutevera aya matipi ekugadzirisa, unogona kurebesa hupenyu hwemuchina, kuve nechokwadi chekuyera uye kuzadza, uye kudzivirira kuparara kunodhura. Rangarira kuchenesa muchina nguva nenguva, kuongorora kusakara uye kubvaruka, kugadzirisa muchina, tarisa zvinhu zvemagetsi, uye kutevedzera magadzirirwo emugadziri. Nekugadzirisa kwakaringana, ako otomatiki nzungu bhinzi cashew magaba anorema ekuzadza mutsara muchina ucharamba uchishanda zvakanaka uye nemazvo, zvichikubatsira kuzadzisa zvinangwa zvako zvekugadzira.

Maintenance Tips for Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.