- 08

- Dec

Automatic Nuts Beans Cashew gasacadaha Miisaamidda Khadka Buuxinta

Faa’iidooyinka Isticmaalka Tooska ah ee Miraha Digirta Cashew gasacadaha Miisaamidda Khadka Buuxinta

Automatic lawska digirta cashew gasacad miisaamaya mashiinada khadka buuxinta ayaa wax ka beddelaya habka ay shirkaduhu u xirxiraan una qaybiyaan alaabtooda. Mashiinnadani waxay bixiyaan faa’iidooyin kala duwan oo ka caawin kara ganacsiyada inay kordhiyaan waxtarka, yareeyaan qashinka, iyo hagaajinta guud ahaan wax soo saarka Mashiinadan waxaa lagu qalabeeyay tignoolajiyad horumarsan oo hubinaysa cabbirada saxda ah ee lawska, digirta, cashews, iyo alaabada kale. Xaqiijinta heerkan ayaa muhiim u ah shirkadaha u baahan in ay la kulmaan heerarka adag ee ilaalinta tayada iyo in la hubiyo in badeecadahoodu ay si joogto ah u baakadeeyeen tirada saxda ah Mashiinnadani waxay awood u leeyihiin inay buuxiyaan oo ku baakeeyaan badeecadaha si ka dhaqso badan hababka gacanta, taasoo u oggolaanaysa shirkadaha inay kordhiyaan wax soo saarkooda oo ay si wax ku ool ah u daboolaan baahida macaamiisha. Waxtarkan korodhay wuxuu u horseedi karaa kaydin kharash iyo faa’iido wanaajinta ganacsiyada mustaqbalka fog Marka si sax ah loo cabbiro oo loo buuxiyo badeecadaha, mashiinnadani waxay ka caawiyaan shirkadaha inay yareeyaan buuxinta iyo buuxinta, taas oo keeni karta qashin weyn waqti ka dib. Tani ma aha oo kaliya kaydinta lacagta ganacsiyada laakiin sidoo kale waxay kaa caawinaysaa yaraynta saameyntooda deegaanka iyadoo hoos u dhigaysa tirada alaabta ku dhamaanaysa meelaha qashinka ah Tani waxay u fududaynaysaa shirkaduhu inay shaqaalahooda u tababaraan sida loo isticmaalo mishiinada si wax ku ool ah, yaraynta khatarta khaladaadka iyo hubinta natiijooyinka joogtada ah. Intaa waxaa dheer, qaar badan oo ka mid ah mishiinadan waxay ku qalabaysan yihiin sifooyin ay ka mid yihiin muraayadaha taabashada iyo barnaamijyada la samayn karo, taas oo u sahlaysa hawlwadeenada inay hagaajiyaan goobaha oo ay habeeyaan mishiinka si ay u daboolaan baahidooda gaarka ah.

Mid ka mid ah faa’iidooyinka ugu muhiimsan ee isticmaalka buuxinta miisaanka tooska ah Mashiinka khadka ayaa ah wax soo saarka guud ee la hagaajiyay ee ay bixiso. Iyadoo la hagaajinayo habka baakadaha iyo yaraynta wakhtiga ay ku qaadato buuxinta iyo baakadaha alaabta, mashiinnadani waxay u oggolaanayaan shirkadaha inay kordhiyaan wax soo saarkooda oo ay si hufan u daboolaan baahida macaamiisha. Tani waxay ka caawin kartaa ganacsiyada inay koraan oo balaadhiyaan hawlahooda iyagoo ilaalinaya tayada tayada sare leh iyo joogtaynta.

Laga soo bilaabo saxnaanta iyo hufnaanta korodhay ilaa hoos u dhaca qashinka iyo wax soo saarka oo la hagaajiyay, mashiinadani waxay ka caawin karaan ganacsiyada inay hagaajiyaan shaqadooda oo ay guulo waaweyn ka gaaraan suuqa. Iyada oo la maalgelinayo mashiinka khadka buuxinta miisaanka tooska ah, shirkaduhu waxay isu dhigi karaan kobaca muddada dheer iyo faa’iidada warshadaha baakadaha tartanka.

Tallooyinka Dayactirka ee Mishiinka Khadka Buuxinta ee Miisaamidda Miraha Miraha Cashew

Digirta lawska si toos ah u miisaama mishiinada khadka buuxinta ayaa ah qalabka lagama maarmaanka u ah warshadaynta cuntada. Mashiinadan waxaa loogu talagalay inay si sax ah u miisaamaan oo ay u buuxiyaan noocyada kala duwan ee looska, digirta, iyo cashews gasacaddo, hubinta tayada badeecada oo joogto ah iyo dhimista shaqada gacanta. Si loo hubiyo habsami u socodka mishiinadan loogana hortago burburka, dayactirka joogtada ahi waa muhiim. Maqaalkan, waxaan kaga hadli doonaa qaar ka mid ah talooyinka dayactirka ee looska lawska ah digirta cashew gasacad miisaamaya mishiinada khadka buuxinta Waqti ka dib, boodhka, qashinka, iyo qaybaha cuntadu waxay ku ururi karaan qaybaha mishiinka, taas oo keenta hoos u dhaca waxtarka iyo cilladaha suurtagalka ah. Waxaa lagu talinayaa in la nadiifiyo mashiinka ka dib isticmaalka kasta, iyadoo fiiro gaar ah u leh hababka miisaanka iyo buuxinta, iyo sidoo kale suumanka gudbinta iyo dareemayaasha. Isticmaal buraash ama maro jilicsan si aad meesha uga saarto wax kasta oo soo kordhay oo aad hubiso in dhammaan qaybaha ay qalalan yihiin ka hor inta aanad mar labaad shaqaynin Iska hubi boolal dabacsan ama boolal, suumanka wax qaada ee dhaawacan, iyo dareemayaasha duugoobay. Isla markiiba u beddel wixii burburay ama gaboobey si aad uga hortagto waxyeello kale oo soo gaadha mishiinka una hubiso in uu sii shaqeeyo. Sidoo kale waa fikrad wanaagsan in la subiyo qaybaha dhaqaaqa, sida gears iyo biraha, si loo yareeyo is jiid jiidka loona kordhiyo cimriga mishiinka Waqti ka dib, hababka miisaamidda iyo buuxinta mishiinka ayaa laga yaabaa inay noqdaan kuwo khaldan, taasoo horseedaysa cabbirro aan sax ahayn iyo tayada alaabta oo aan waafaqsanayn. Si loo hubiyo miisaanka saxda ah iyo buuxinta, qiyaas mashiinka sida waafaqsan tilmaamaha soo saaraha. Tani waxa ay ku lug yeelan kartaa hagaajinta habaynta guddida kantaroolka ama isticmaalka miisaannada cabbirka si loo xaqiijiyo saxnaanta mishiinka Ka eeg fiilooyinka, xirayaasha, iyo guddiga koontaroolka wixii calaamado ah ee waxyeelo ama daxalka ah. Xidhiidhada dabacsan ama fiilooyinka khaldan waxay sababi karaan cillad koronto waxayna keeni karaan khatar badbaado. Haddii aad wax arrimo ah ku aragto qaybaha korantada, la xidhiidh farsamo yaqaan aqoon u leh si aad u hagaajiso ama u badasho Tan waxa ku jiri kara kormeero xilliyo ah, nadiifin, sifeyn, iyo hawlo hagaajin. Markaad raacdo tilmaamaha soo saaraha, waxaad xaqiijin kartaa in mishiinku u shaqeeyo si hufan oo la isku halleyn karo, yaraynta khatarta burburka iyo dayactirka kharashka badan Markaad raacdo talooyinka dayactirka, waxaad sii dheerayn kartaa cimriga mishiinka, waxaad hubisaa miisaan sax ah iyo buuxin, kana hortagto burburka qaaliga ah. Xusuusnow inaad si joogto ah u nadiifiso mishiinka, u baadh jeexjeexa iyo jeexjeexa, cabbir mishiinka, hubi qaybaha korontada, oo raac jadwalka dayactirka soo saaraha. Dayactirka saxda ah, nuts si toos ah digirta cashew gasacad miisaamaya mashiinka khadka buuxinta ayaa sii wadi doona inuu u shaqeeyo si habsami leh oo hufan, kaa caawinaya inaad gaarto yoolalkaaga wax soo saarka.

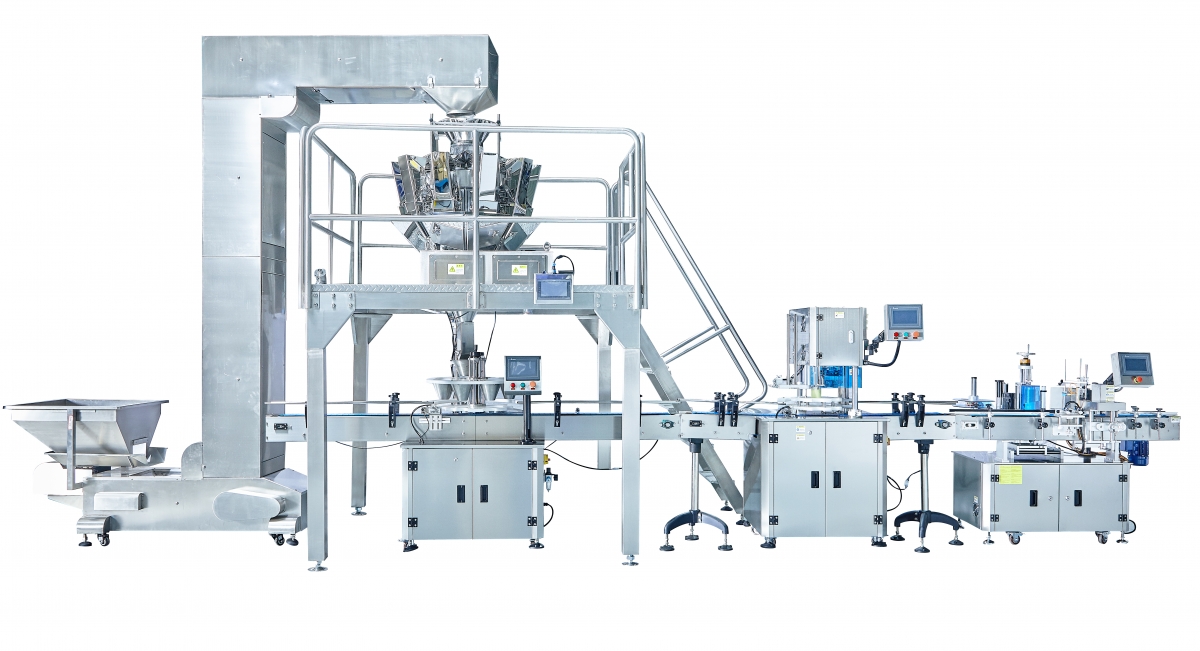

When it comes to packaging products like nuts, beans, cashews, and cans, having an efficient weighing and filling line machine is essential for any business. These machines can help streamline the packaging process, increase productivity, and ensure accurate measurements for each product. However, with so many options available on the market, choosing the right automatic nuts beans cashew cans weighing filling line machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting the best machine for your needs.

One of the first things to consider when choosing an automatic weighing and filling line machine is the type of products you will be packaging. Different machines are designed to handle specific types of products, so it is important to choose a machine that is suitable for the size, shape, and weight of the items you will be packaging. For example, if you will be packaging small nuts and beans, you may need a machine with a high level of precision and accuracy. On the other hand, if you will be packaging larger items like cans, you may need a machine with a higher capacity and faster filling speed.

Another important factor to consider is the speed and efficiency of the machine. Depending on the volume of products you will be packaging, you may need a machine that can fill and weigh a large number of items quickly and accurately. Look for machines that have a high filling speed and can handle a wide range of product sizes to ensure maximum efficiency in your packaging process.

In addition to speed and efficiency, it is also important to consider the accuracy of the machine. Accurate measurements are crucial for ensuring that each product is packaged correctly and that you are not wasting any materials. Look for machines that have built-in sensors and technology to ensure precise weighing and filling of each item.

When choosing an automatic weighing and filling line machine, it is also important to consider the overall size and footprint of the machine. Make sure that the machine will fit comfortably in your production space and that it is easy to operate and maintain. Look for machines that are user-friendly and come with clear instructions and support from the manufacturer.

Finally, consider the cost of the machine and your budget. Automatic weighing and filling line machines can vary greatly in price depending on their features and capabilities. It is important to choose a machine that fits within your budget while still meeting your needs for speed, accuracy, and efficiency.

In conclusion, choosing the right automatic nuts beans cashew cans weighing filling line machine for your business is a crucial decision that can have a significant impact on your packaging process. Consider factors such as the type of products you will be packaging, the speed and efficiency of the machine, accuracy, size, and cost when making your decision. By taking the time to research and evaluate your options, you can find a machine that will help streamline your packaging process and improve the overall efficiency of your business.

Maintenance Tips for Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.