- 08

- Dec

全自動堅果豆類腰果罐秤重填充線機

使用全自動堅果豆類腰果罐稱重填充線機的好處

如何為您的企業選擇合適的自動堅果豆類腰果罐稱重填充線機器

全自動堅果豆類腰果罐秤重填充線機的保養技巧

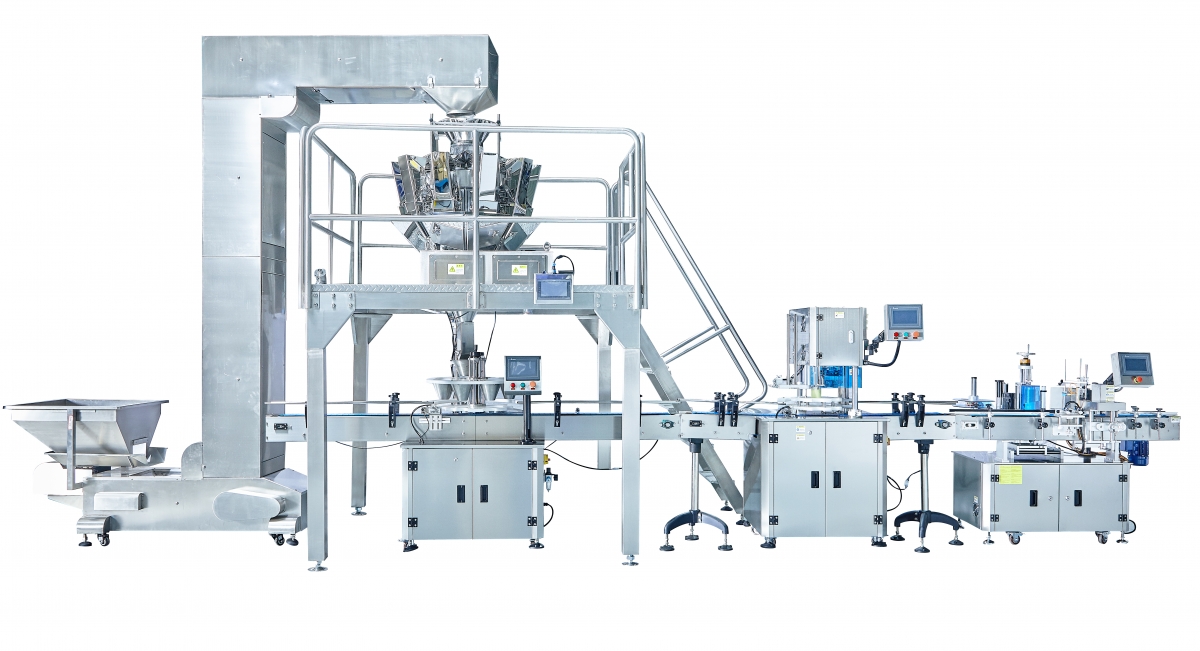

全自動堅果豆類腰果罐頭稱重填充線機是食品加工行業必不可少的設備。這些機器旨在準確地稱重各種類型的堅果、豆類和腰果並將其裝入罐中,確保一致的產品品質並減少體力勞動。為了確保這些機器的順利運作並防止故障,定期維護至關重要。在本文中,我們將討論自動堅果、豆類、腰果罐頭稱重填充線機器的一些維護技巧。隨著時間的推移,灰塵、碎片和食物顆粒會積聚在機器的組件上,導致效率降低和潛在的故障。建議每次使用後清潔機器,特別注意稱重和填充機構以及傳送帶和感測器。使用軟刷或軟布清除任何堆積物,並確保所有部件乾燥後再操作機器。檢查螺栓或螺絲是否鬆動、傳送帶是否損壞以及感測器是否磨損。立即更換任何損壞或磨損的零件,以防止機器進一步損壞並確保其繼續運作。潤滑齒輪和軸承等運動部件也是一個好主意,以減少摩擦並延長機器的使用壽命。隨著時間的推移,機器的稱重和填充機構可能會錯位,從而導致測量不準確和產品品質不一致。為確保準確稱重和填充,請根據製造商的說明校準機器。這可能涉及調整控制面板上的設定或使用校準砝碼來驗證機器的準確性。檢查接線、連接器和控制面板是否有任何損壞或腐蝕的跡象。連接鬆動或接線錯誤可能會導致電氣故障並造成安全隱患。如果您發現電氣元件有任何問題,請聯絡合格的技術人員進行維修或更換。這可能包括定期檢查、清潔、潤滑和校準任務。透過遵循製造商的指南,您可以確保機器高效可靠地運行,從而降低故障和昂貴的維修風險。關重要。遵循這些維護技巧,您可以延長機器的使用壽命,確保準確的稱重和填充,並防止代價高昂的故障。請記住定期清潔機器,檢查磨損情況,校準機器,檢查電氣元件,並遵循製造商的維護計劃。透過適當的維護,您的自動堅果、豆類、腰果罐頭稱重填充線機器將繼續平穩、高效地運行,幫助您實現生產目標。

When choosing an automatic weighing and filling line machine, it is also important to consider the overall size and footprint of the machine. Make sure that the machine will fit comfortably in your production space and that it is easy to operate and maintain. Look for machines that are user-friendly and come with clear instructions and support from the manufacturer.

Finally, consider the cost of the machine and your budget. Automatic weighing and filling line machines can vary greatly in price depending on their features and capabilities. It is important to choose a machine that fits within your budget while still meeting your needs for speed, accuracy, and efficiency.

In conclusion, choosing the right automatic nuts beans cashew cans weighing filling line machine for your business is a crucial decision that can have a significant impact on your packaging process. Consider factors such as the type of products you will be packaging, the speed and efficiency of the machine, accuracy, size, and cost when making your decision. By taking the time to research and evaluate your options, you can find a machine that will help streamline your packaging process and improve the overall efficiency of your business.

Maintenance Tips for Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.