- 08

- Dec

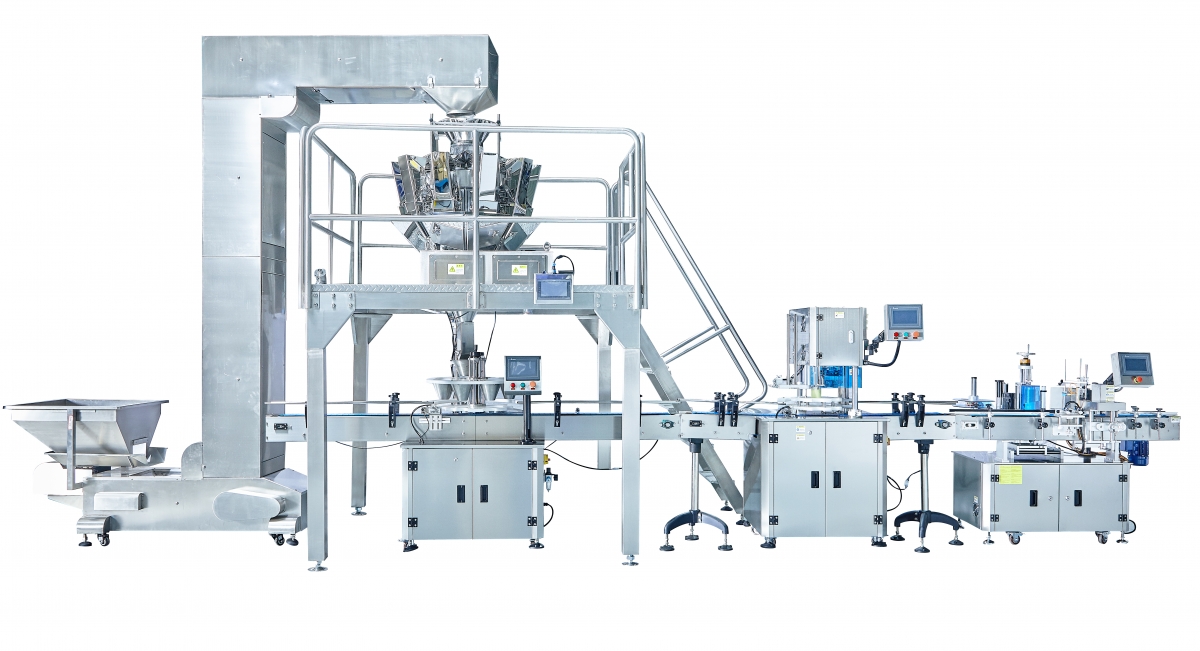

Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Izinzuzo Zokusebenzisa Umshini Wokugcwalisa Wamantongomane Okuzenzakalelayo

Ungakhetha Kanjani Umshini Wokugcwalisa Wamantongomane Okuzenzakalelayo Ofanele Webhizinisi Lakho

Uma kuziwa emikhiqizweni yokupakisha efana namantongomane, ubhontshisi, ama-cashews, namathini, ukuba nomshini wokukala nokugcwalisa osebenza kahle kubalulekile kunoma yiliphi ibhizinisi. Le mishini ingasiza ukwenza lula inqubo yokupakisha, ikhulise ukukhiqiza, futhi iqinisekise izilinganiso ezinembile zomkhiqizo ngamunye. Kodwa-ke, ngezinketho eziningi ezitholakalayo emakethe, ukukhetha amathini ama-cashew amantongomane azenzakalelayo anesisindo somshini wokugcwalisa webhizinisi lakho kungaba umsebenzi onzima. Kulesi sihloko, sizoxoxa ngezinto ezithile ezibalulekile okufanele uzicabangele lapho ukhetha umshini ongcono kakhulu wezidingo zakho.

Enye yezinto zokuqala okufanele uzicabangele lapho ukhetha umshini wokulinganisa okuzenzakalelayo nokugcwalisa uhlobo lwemikhiqizo ozobe uyipakisha. Imishini ehlukene yakhelwe ukuphatha izinhlobo ezithile zemikhiqizo, ngakho-ke kubalulekile ukukhetha umshini ofanele usayizi, umumo, nesisindo sezinto ozozipakisha. Isibonelo, uma uzobe upakisha amantongomane amancane nobhontshisi, ungase udinge umshini onezinga eliphezulu lokunemba nokunemba. Ngakolunye uhlangothi, uma uzobe upakisha izinto ezinkulu njengamathini, ungase udinge umshini onomthamo ophezulu kanye nesivinini sokugcwalisa ngokushesha.

Esinye isici esibalulekile okufanele sicatshangelwe ijubane nokusebenza kahle komshini. Kuye ngevolumu yemikhiqizo ozoyipakisha, ungase udinge umshini ongagcwalisa futhi ulinganise inani elikhulu lezinto ngokushesha nangokunembile. Bheka imishini enejubane eliphezulu lokugcwalisa futhi ingakwazi ukuphatha ububanzi obuningi bosayizi womkhiqizo ukuze uqinisekise ukusebenza kahle okukhulu ohlelweni lwakho lokupakisha.

Ngaphezu kwesivinini nokusebenza kahle, kubalulekile ukucabangela ukunemba komshini. Izilinganiso ezinembile zibalulekile ekuqinisekiseni ukuthi umkhiqizo ngamunye upakishwe ngendlela efanele nokuthi awumoshi lutho. Bheka imishini enezinzwa ezakhelwe ngaphakathi kanye nobuchwepheshe ukuze uqinisekise ukukala okunembile nokugcwaliswa kwento ngayinye.

Uma ukhetha umshini wokukala othomathikhi nokugcwalisa umugqa, kubalulekile futhi ukucabangela usayizi jikelele kanye nokunyathelisa kwezinyawo zomshini. Qiniseka ukuthi umshini uzolingana ngokunethezeka endaweni yakho yokukhiqiza nokuthi kulula ukuyisebenzisa nokuyinakekela. Bheka imishini esebenziseka kalula futhi eza neziqondiso ezicacile nokusekelwa okuvela kumkhiqizi.

Ekugcineni, cabangela izindleko zomshini kanye nesabelomali sakho. Imishini yokukala neyokugcwalisa ezenzakalelayo ingahluka kakhulu ngentengo kuye ngezici namandla abo. Kubalulekile ukukhetha umshini olingana nesabelomali sakho ube usahlangabezana nezidingo zakho zejubane, ukunemba, nokusebenza kahle.

ingaba nomthelela omkhulu ohlelweni lwakho lokupakisha. Cabangela izici ezifana nohlobo lwemikhiqizo ozoyipakisha, isivinini nokusebenza kahle komshini, ukunemba, usayizi, kanye nezindleko uma wenza isinqumo sakho. Ngokuthatha isikhathi sokucwaninga nokuhlola izinketho zakho, ungathola umshini ozokusiza ukuqondisa inqubo yakho yokupakisha futhi uthuthukise ukusebenza kahle konke kwebhizinisi lakho.

Amathiphu Okulungisa Ama-Automatic Nuts Beans Cashew Cans Weighing Filling Line Machine

Amathini ama-automatic beans kashew cans anesisindo semishini yokugcwalisa iyimpahla ebalulekile embonini yokucubungula ukudla. Le mishini iklanyelwe ukukala ngokunembile futhi igcwalise izinhlobo ezihlukahlukene zamantongomane, ubhontshisi, nama-cashews emathinini, kuqinisekiswe ikhwalithi yomkhiqizo engashintshi kanye nokunciphisa umsebenzi wezandla. Ukuqinisekisa ukusebenza kahle kwale mishini futhi kuvinjwe ukuwohloka, ukunakekelwa njalo kubalulekile. Kulesi sihloko, sizoxoxa ngamathiphu athile okunakekela amathini ama-cashew amantongomane azenzakalelayo anesisindo semishini yomugqa wokugcwalisa.

Omunye wemisebenzi ebaluleke kakhulu yokunakekela le mishini ukuhlanza njalo. Ngokuhamba kwesikhathi, uthuli, udoti, nezinhlayiya zokudla zinganqwabelana ezingxenyeni zomshini, okuholela ekwehleni kokusebenza kahle kanye nokungasebenzi kahle okungenzeka. Kunconywa ukuhlanza umshini ngemva kokusetshenziswa ngakunye, ukunaka ngokukhethekile izindlela zokukala nokugcwalisa, kanye namabhande okuthutha kanye nezinzwa. Sebenzisa ibhulashi elithambile noma indwangu ukuze ukhiphe noma yikuphi ukunqwabelanisa futhi uqinisekise ukuthi zonke izingxenye zomile ngaphambi kokuba usebenzise umshini futhi.

Ngaphezu kokuhlanza, kubalulekile ukuhlola umshini njalo ukuze uthole noma yiziphi izimpawu zokuguga nokukhala. Hlola amabhawudi axegayo noma izikulufu, amabhande okuthutha alimele, nezinzwa ezigugile. Shintsha noma yiziphi izingxenye ezilimele noma ezigugile ngokushesha ukuze uvimbele ukulimala okwengeziwe emshinini futhi uqinisekise ukusebenza kwawo okuqhubekayo. Kungumqondo omuhle futhi ukugcoba izingxenye ezihambayo, njengamagiya namabheringi, ukuze kuncishiswe ukungqubuzana nokwelula isikhathi sokuphila komshini.

Ukulinganiswa komshini kungomunye umsebenzi obalulekile wokulungisa okufanele wenziwe njalo. Ngokuhamba kwesikhathi, izindlela zokukala nokugcwalisa zomshini zingase zingahambi kahle, okuholela esilinganisweni esingalungile kanye nekhwalithi yomkhiqizo engahambisani. Ukuqinisekisa ukukala nokugcwalisa okunembile, linganisa umshini ngokwemiyalelo yomkhiqizi. Lokhu kungase kuhlanganise ukulungisa izilungiselelo kuphaneli yokulawula noma ukusebenzisa izisindo zokulinganisa ukuze kuqinisekiswe ukunemba komshini.

Ukuhlola njalo izingxenye zikagesi zomshini nakho kubalulekile ekusebenzeni kwawo okufanele. Hlola izintambo, izixhumi, nephaneli yokulawula ukuze uthole noma yiziphi izimpawu zokulimala noma ukugqwala. Ukuxhuma okuxekethile noma izintambo ezinephutha kungabangela ukungasebenzi kahle kukagesi futhi kube yingozi yokuphepha. Uma ubona noma yiziphi izinkinga ngezingxenye zikagesi, thinta uchwepheshe oqeqeshiwe ukuze azilungise noma azishintshe.

Okokugcina, kubalulekile ukulandela isimiso esinconywa ngumkhiqizi sokulungisa amathini kashew angenantambo anesisindo somshini wokugcwalisa amantongomane ubhontshisi. Lokhu kungase kuhlanganise ukuhlolwa ngezikhathi ezithile, ukuhlanza, ukuthambisa, kanye nemisebenzi yokulinganisa. Ngokulandela iziqondiso zomkhiqizi, ungaqinisekisa ukuthi umshini usebenza ngendlela efanele futhi enokwethenjelwa, unciphisa ingcuphe yokuphuka kanye nokulungiswa okumba eqolo.

Sengiphetha, ukunakekelwa okuvamile kubalulekile ukuze kusebenze kahle amathini kashew amantongomane kabhontshisi anesisindo semishini yolayini wokugcwalisa. Ngokulandela lawa macebiso okunakekela, ungakwazi ukwelula isikhathi sokuphila komshini, uqinisekise ukukala okunembile nokugcwalisa, futhi uvimbele ukuwohloka okumba eqolo. Khumbula ukuhlanza umshini njalo, ukuhlola ukuguga nokukhala, ukulinganisa umshini, ukuhlola izingxenye zikagesi, futhi ulandele isimiso sokuwunakekela komenzi. Ngokulungiswa okufanele, amathini akho e-cashew amantongomane azenzakalelayo anesisindo somugqa wokugcwalisa azoqhubeka nokusebenza ngokushelela nangempumelelo, akusize uhlangabezane nezinhloso zakho zokukhiqiza.

Automatic nuts beans cashew cans weighing filling line machines are essential equipment in the food processing industry. These machines are designed to accurately weigh and fill various types of nuts, beans, and cashews into cans, ensuring consistent product quality and reducing manual labor. To ensure the smooth operation of these machines and prevent breakdowns, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic nuts beans cashew cans weighing filling line machines.

One of the most important maintenance tasks for these machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine after each use, paying special attention to the weighing and filling mechanisms, as well as the conveyor belts and sensors. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, it is essential to regularly inspect the machine for any signs of wear and tear. Check for loose bolts or screws, damaged conveyor belts, and worn-out sensors. Replace any damaged or worn parts immediately to prevent further damage to the machine and ensure its continued operation. It is also a good idea to lubricate moving parts, such as gears and bearings, to reduce friction and extend the machine’s lifespan.

Calibrating the machine is another important maintenance task that should be performed regularly. Over time, the machine’s weighing and filling mechanisms may become misaligned, leading to inaccurate measurements and inconsistent product quality. To ensure accurate weighing and filling, calibrate the machine according to the manufacturer’s instructions. This may involve adjusting the settings on the control panel or using calibration weights to verify the machine’s accuracy.

Regularly checking the machine’s electrical components is also crucial for its proper functioning. Inspect the wiring, connectors, and control panel for any signs of damage or corrosion. Loose connections or faulty wiring can cause electrical malfunctions and pose a safety hazard. If you notice any issues with the electrical components, contact a qualified technician to repair or replace them.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the automatic nuts beans cashew cans weighing filling line machine. This may include periodic inspections, cleaning, lubrication, and calibration tasks. By following the manufacturer’s guidelines, you can ensure that the machine operates efficiently and reliably, reducing the risk of breakdowns and costly repairs.

In conclusion, regular maintenance is essential for the proper functioning of automatic nuts beans cashew cans weighing filling line machines. By following these maintenance tips, you can prolong the machine’s lifespan, ensure accurate weighing and filling, and prevent costly breakdowns. Remember to clean the machine regularly, inspect for wear and tear, calibrate the machine, check the electrical components, and follow the manufacturer’s maintenance schedule. With proper maintenance, your automatic nuts beans cashew cans weighing filling line machine will continue to operate smoothly and efficiently, helping you meet your production goals.